2021 High quality Lng Plant Equipment - Vacuum Insulated Check Valve – Holy

2021 High quality Lng Plant Equipment - Vacuum Insulated Check Valve – Holy Detail:

Product Application

The product series of Vacuum Valve, Vacuum Pipe, Vacuum Hose and Phase Separator in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (e.g. cryogenic storage tank, dewar and coldbox etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, pharmacy, biobank, food & beverage, automation assembly, chemical engineering, iron & steel, and scientific research etc.

Vacuum Insulated Shut-off Valve

The Vacuum Insulated Check Valve, namely Vacuum Jacketed Check Valve, is used when liquid medium is not allowed to flow back.

Cryogenic liquids and gases in the VJ pipeline are not allowed to flow back when cryogenic storage tanks or equipment under safety requirements. The backflow of cryogenic gas and liquid may cause excessive pressure and damage to equipment. At this time, it is necessary to equip the Vacuum Insulated Check Valve at the appropriate position in the vacuum insulated pipeline to ensure that the cryogenic liquid and gas will not flow back beyond this point.

In the manufacturing plant, Vacuum Insulated Check Valve and the VI pipe or hose prefabricated into a pipeline, without on-site pipe installation and insulation treatment.

For more personalized and detailed questions about the VI Valve series, please contact HL Cryogenic Equipment Company directly, we will serve you whole-heartedly!

Parameter Information

| Model | HLVC000 Series |

| Name | Vacuum Insulated Check Valve |

| Nominal Diameter | DN15 ~ DN150 (1/2″ ~ 6″) |

| Design Temperature | -196℃~ 60℃ (LH2 & LHe:-270℃ ~ 60℃) |

| Medium | LN2, LOX, LAr, LHe, LH2, LNG |

| Material | Stainless Steel 304 |

| On-site Installation | No, |

| On-site Insulated Treatment | No |

HLVC000 Series, 000 represents the nominal diameter, such as 025 is DN25 1″ and 150 is DN150 6″.

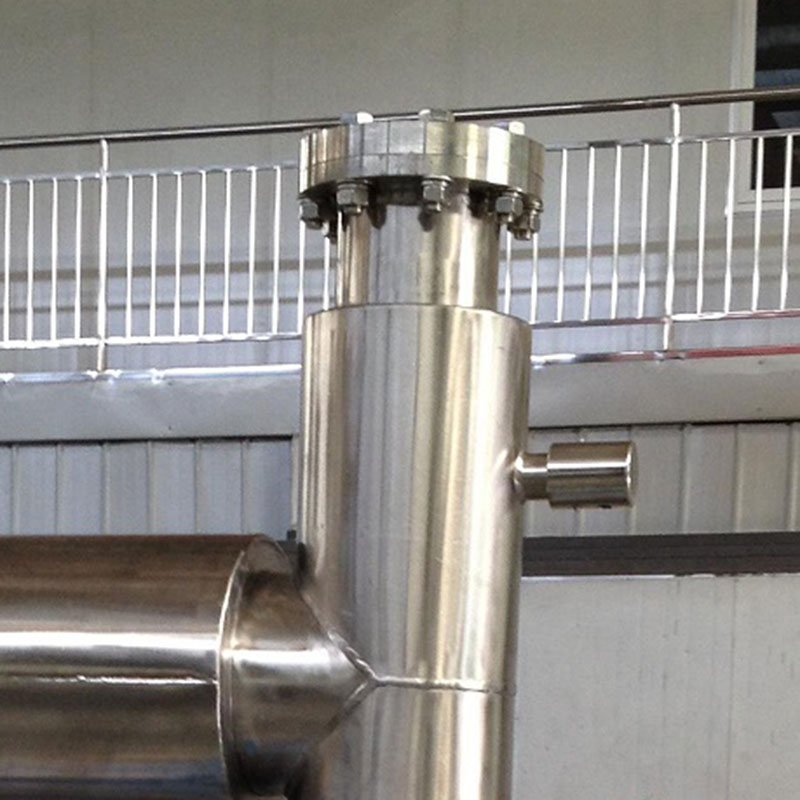

Product detail pictures:

Related Product Guide:

We have been commitment to supply the competitive price ,excellent products and solutions high-quality, at the same time as fast delivery for 2021 High quality Lng Plant Equipment - Vacuum Insulated Check Valve – Holy , The product will supply to all over the world, such as: Hanover, Lisbon, Lebanon, We have gained a lot of recognition among customers spread all across the world. They trust us and always give repetitive orders. Furthermore, mentioned below are some of the major factors that have played significant role in our tremendous growth in this domain.

We have been looking for a professional and responsible supplier, and now we find it.