China Vacuum LIN Phase Separator Series

Product Brief Description:

- Superior Phase Separation: Our China Vacuum LIN Phase Separator Series provides highly effective separation of liquid and gas phases, enhancing industrial processing efficiency.

- Customization Options: We offer tailored solutions to meet specific industrial requirements, ensuring seamless integration and optimized performance for diverse applications.

- Robust Construction: Built to withstand demanding industrial environments, our phase separator series is crafted with durability and reliability in mind, minimizing maintenance needs and operational disruptions.

- Industry-Leading Manufacturing: As a prominent production factory, we adhere to stringent quality standards and advanced manufacturing processes, delivering high-quality phase separators for industrial use.

Product Details Description: Highly Effective Phase Separation for Enhanced Processing Efficiency: The China Vacuum LIN Phase Separator Series is designed to deliver exceptional phase separation capabilities, facilitating efficient industrial processing. Through advanced engineering and precision design, our phase separators effectively separate liquid and gas phases, ensuring optimal processing conditions and enhancing overall production efficiency. This superior phase separation capability contributes to improved productivity, reduced processing time, and enhanced product quality, making our phase separator series a valuable asset for industrial applications requiring precise separation processes.

Tailored Solutions for Seamless Integration and Performance Optimization: Understanding the diverse needs of industrial applications, we offer customization options for our China Vacuum LIN Phase Separator Series. By providing tailored solutions to accommodate specific industrial requirements, we enable seamless integration and optimized performance for a wide range of processing environments. Whether it's adapting to unique operational demands or aligning with specific processing parameters, our customizable phase separators empower industrial facilities to maximize efficiency and achieve precision separation tailored to their exact needs.

Robust Construction for Long-Term Reliability and Operational Resilience: Crafted with durability in mind, our phase separator series features a robust construction that can withstand the rigors of demanding industrial environments. From high-quality materials to meticulous fabrication, these phase separators are engineered to minimize maintenance needs and operational disruptions, ensuring consistent and reliable performance over extended periods. This resilience not only reduces downtime and maintenance costs but also contributes to uninterrupted industrial processes, enhancing overall operational efficiency and reliability.

Adherence to Stringent Quality Standards and Advanced Manufacturing Processes: As a reputable production factory, we maintain a steadfast commitment to adherence to stringent quality standards and advanced manufacturing processes in the production of our China Vacuum LIN Phase Separator Series. Every phase separator undergoes rigorous testing and inspection to ensure that it meets our high-quality benchmarks for performance and reliability. By upholding these industry-leading practices, we deliver phase separators that meet the demanding requirements of industrial applications, providing dependable and efficient phase separation solutions for diverse processing needs.

In summary, our China Vacuum LIN Phase Separator Series delivers highly effective phase separation, customization options, robust construction, and adherence to stringent quality standards, making it an invaluable solution for efficient industrial processing. With a focus on enhancing processing efficiency, reliability, and tailored integration, our phase separator series is designed to meet the diverse needs of industrial applications, providing a dependable and high-performance solution for precise phase separation requirements.

Product Application

The product series of Phase Separator, Vacuum Pipe, Vacuum Hose and Vacuum Valve in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (e.g. cryogenic storage tank, dewar and coldbox etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, pharmacy, biobank, food & beverage, automation assembly, chemical engineering, iron & steel, rubber, new material manufacturing and scientific research etc.

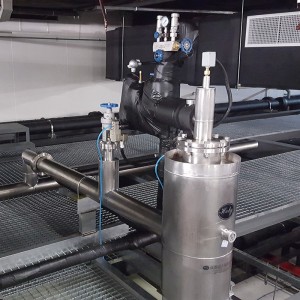

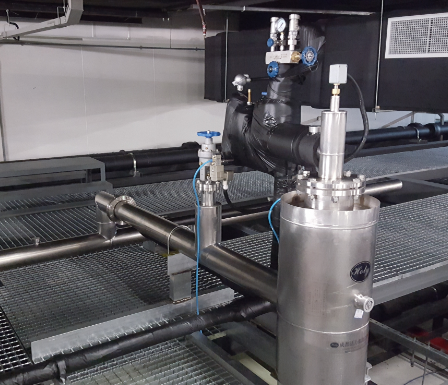

Vacuum Insulated Phase Separator

HL Cryogenic Equipment Company has four kinds of Vacuum Insulated Phase Separator, their name are,

- VI Phase Separator -- (HLSR1000 series)

- VI Degasser -- (HLSP1000 series)

- VI Automatic Gas Vent -- (HLSV1000 series)

- VI Phase Separator for MBE System -- (HLSC1000 series)

No matter which kind of the Vacuum Insulated Phase Separator, it is one of the most common equipment of Vacuum Insulated Cryogenic Piping System. The phase separator is mainly to separate the gas from the liquid nitrogen, which can ensure,

1. Liquid supply volume and speed: Eliminate insufficient liquid flow and velocity caused by gas barrier.

2. Incoming temperature of terminal equipment: eliminate the temperature instability of cryogenic liquid due to slag inclusion in gas, which leads to the production conditions of terminal equipment.

3. Pressure adjustment (reducing) and stability: eliminate the pressure fluctuation caused by the continuous formation of gas.

In a word, VI Phase Separator function is to meet the requirements of the terminal equipment for liquid nitrogen, including flow rate, pressure, and temperature and so on.

The Phase Separator is a mechanical structure and system that does not require pneumatic and electrical source. Usually choose 304 stainless steel production, can also choose other 300 series stainless steel according to the requirements. The Phase Separator is mainly used for liquid nitrogen service and recommended to be placed at the highest point of the piping system to ensure maximum effect, since gas has a lower specific gravity than liquid.

About the Phase Separator / Vapor Vent more personalized and detailed questions, please contact HL Cryogenic Equipment directly, we will serve you whole-heartedly!

Parameter Information

| Name | Degasser |

| Model | HLSP1000 |

| Pressure Regulation | No |

| Power Source | No |

| Electric Control | No |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 8~40L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 265 W/h (when 40L) |

| Heat Loss When Is Stable | 20 W/h (when 40L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Phase Separator |

| Model | HLSR1000 |

| Pressure Regulation | Yes |

| Power Source | Yes |

| Electric Control | Yes |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 8L~40L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 265 W/h (when 40L) |

| Heat Loss When Is Stable | 20 W/h (when 40L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Automatic Gas Vent |

| Model | HLSV1000 |

| Pressure Regulation | No |

| Power Source | No |

| Electric Control | No |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 4~20L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 190W/h (when 20L) |

| Heat Loss When Is Stable | 14 W/h (when 20L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Special Phase Separator for MBE Equipment |

| Model | HLSC1000 |

| Pressure Regulation | Yes |

| Power Source | Yes |

| Electric Control | Yes |

| Automatic Working | Yes |

| Design Pressure | Determine according to MBE Equipment |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | ≤50L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 300 W/h (when 50L) |

| Heat Loss When Is Stable | 22 W/h (when 50L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description | A Special Phase Separator for MBE equipment with Multiple Cryogenic Liquid Inlet and Outlet with automatic control function meets the requirement of gas emission, recycled liquid nitrogen and temperature of liquid nitrogen. |