Gas Lock

Product Application

The all series of vacuum jacketed equipment in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (e.g. cryogenic tanks and dewars etc.) in industries of gases, aviation, electronics, superconductor, chips, pharmacy, hospital, bio bank, food & beverage, automation assembly, new materials, rubber manufacturing and scientific research etc.

Vacuum Insulated Shut-off Valve

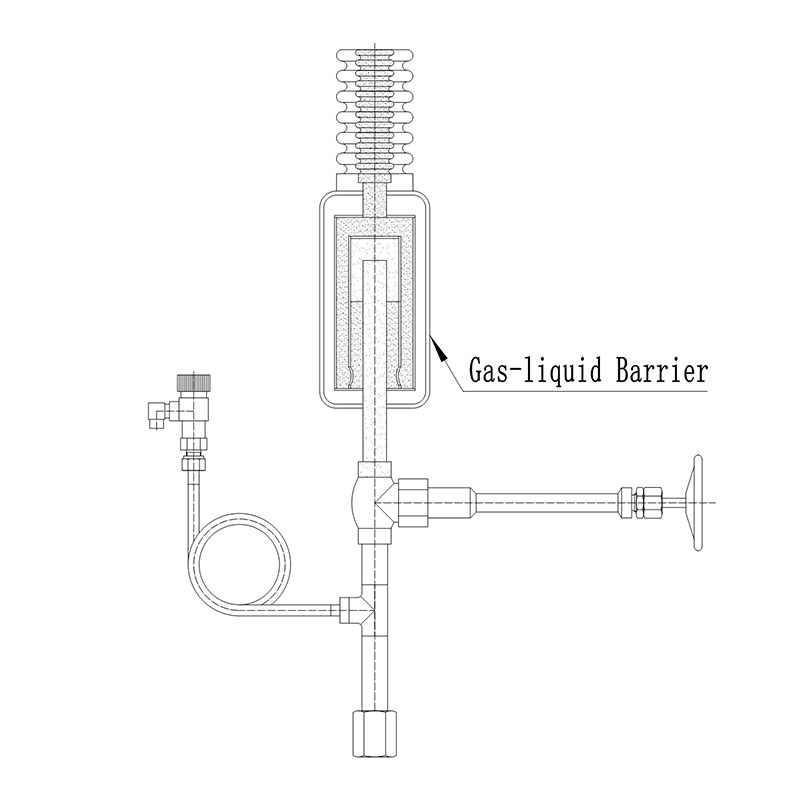

The Vacuum Gas Lock is placed in the vertical VJ pipe at the end of VJ piping. The Gas Lock uses the gas seal principle to block the heat from the end of the VJ pipe into the whole VJ Piping, and effectively reduce the loss of liquid nitrogen during discontinuous and intermittent service of the system.

Because there is usually a small section of non-vacuum pipe at the end of the VJ piping where it is connected to the terminal equipment, this part of the non-vacuum pipe will bring a huge heat loss to the whole vacuum system. A difference of more than 200 degrees Celsius between the ambient temperature and the liquid nitrogen of -196 °C would result in significant gasification (loss of liquid nitrogen) in the VJ piping, while the large amount of vaporization would also cause pressure instability in the VJ piping.

The vacuum gas-liquid barrier is designed to limit this heat transfer into the VJ piping and to minimize liquid nitrogen losses during frequent discontinuous use of liquid nitrogen in terminal equipment.

The Gas Lock does not require power to operate. It and VI Pipe or Hose are prefabricated into one pipeline in the manufactory, and there is no need for installation and insulated treatment on site.

More detailed and personalized questions, please contact HL cryogenic equipment directly, we will serve you wholeheartedly!

Parameter Information

| Model | HLEB000 Series |

| Nominal Diameter | DN10 ~ DN25 (1/2" ~ 1") |

| Medium | LN2 |

| Material | 300 Series Stainless Steel |

| On-site Installation | No |

| On-site Insulated Treatment | No |