LN2 Filter

Product Brief Description: Our LN2 Filter is a cutting-edge liquid nitrogen filtration solution designed to meet the needs of production factories. With advanced technology and superior craftsmanship, this filter effectively removes impurities and contaminants, ensuring the purity and quality of liquid nitrogen.

Key Features and Company Advantages:

- High Efficiency Filtration: Our LN2 Filter utilizes state-of-the-art filtration technology to efficiently remove impurities, particles, and contaminants from liquid nitrogen, ensuring a clean and pure supply.

- Enhanced Production Efficiency: By eliminating impurities, our LN2 Filter helps to enhance the performance of machinery and equipment that employs liquid nitrogen, thus improving overall production efficiency.

- Cost-effective Solution: Investing in our LN2 Filter allows you to reduce maintenance costs and optimize production processes, leading to long-term savings for your factory.

- Durable and Reliable: Made from high-quality materials, our LN2 Filter is built to withstand the harshest operating conditions, ensuring its durability and reliability.

- Customizable Options: We offer a range of customizable options, including different filtration levels, sizes, and configurations, to suit the specific requirements of your production facility.

Product Details:

- Advanced Filtration Technology: Our LN2 Filter utilizes advanced filtration technology, including a multi-stage filtration system, to effectively remove impurities from liquid nitrogen. The filter's design ensures thorough filtration, capturing even the smallest particles and contaminants.

- Easy Installation and Maintenance: The LN2 Filter is designed for easy installation and maintenance. The user-friendly design allows for hassle-free filter replacement and cleaning, minimizing downtime and optimizing productivity.

- Superior Performance and Efficiency: Thanks to its high-quality components and advanced filtration technology, our LN2 Filter delivers superior performance and efficiency. By removing impurities and contaminants, it helps to protect valuable equipment and ensure consistent, high-quality output.

- Long Service Life: Our LN2 Filter is built to last. The durable construction ensures a long service life, reducing the need for frequent replacements and lowering overall maintenance costs.

- Wide Applications: The LN2 Filter is suitable for various industries, including food processing, pharmaceuticals, semiconductor manufacturing, and cryogenic research. It provides reliable filtration for liquid nitrogen used in cryogenic storage, cooling systems, and other critical processes.

In conclusion, our LN2 Filter offers an efficient and reliable solution for liquid nitrogen filtration in production factories. With advanced technology, customizable options, and superior performance, it helps improve production efficiency, reduce costs, and ensure the purity and quality of liquid nitrogen for various applications. Contact us today to learn more about how our LN2 Filter can enhance your production processes.

Product Application

The all series of vacuum insulated equipment in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (cryogenic tanks and dewar flasks etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, pharmacy, hospital, biobank, food & beverage, automation assembly, rubber, new material manufacturing and scientific research etc.

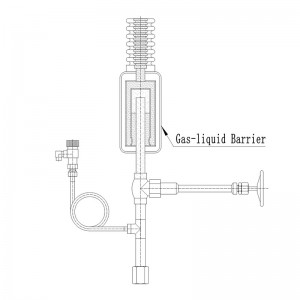

Vacuum Insulated Filter

The Vacuum Insulated Filter, namely Vacuum Jacketed Filter, is used to filter impurities and possible ice residue from liquid nitrogen storage tanks.

The VI Filter can effectively prevent the damage caused by impurities and ice residue to the terminal equipment, and improve the service life of the terminal equipment. In particular, it is strongly recommend for high value terminal equipment.

The VI Filter is installed in front of main line of VI pipeline. In the manufacturing plant, the VI Filter and VI Pipe or Hose are prefabricated into one pipeline, and there is no need for installation and insulated treatment on site.

The reason why the ice slag appears in the storage tank and vacuum jacketed piping is that when the cryogenic liquid is filled at the first time, the air in the storage tanks or VJ piping is not exhausted in advance, and the moisture in the air freezes when it gets cryogenic liquid. Therefore, it is highly recommended to purge the VJ piping for the first time or for the recovery of the VJ piping when it is injected with cryogenic liquid. Purge can also effectively remove the impurities deposited inside the pipeline. However, installing a vacuum insulated filter is a better option and double safe measure.

For more personalized and detailed questions, please contact HL Cryogenic Equipment Company directly, we will serve you whole-heartedly!

Parameter Information

| Model | HLEF000 Series |

| Nominal Diameter | DN15 ~ DN150 (1/2" ~ 6") |

| Design Pressure | ≤40bar (4.0MPa) |

| Design Temperature | 60℃ ~ -196℃ |

| Medium | LN2 |

| Material | 300 Series Stainless Steel |

| On-site Installation | No |

| On-site Insulated Treatment | No |