Dynamic Vacuum System: The Future of Vacuum Insulated Piping

The Dynamic Vacuum System is revolutionizing vacuum insulated piping (VIP) applications, offering a robust solution for industries requiring precision and efficiency in cryogenic fluid transportation. This article explores the features, advantages, and applications of Dynamic Vacuum System, highlighting its pivotal role in modern industrial setups.

How the Dynamic Vacuum System Works

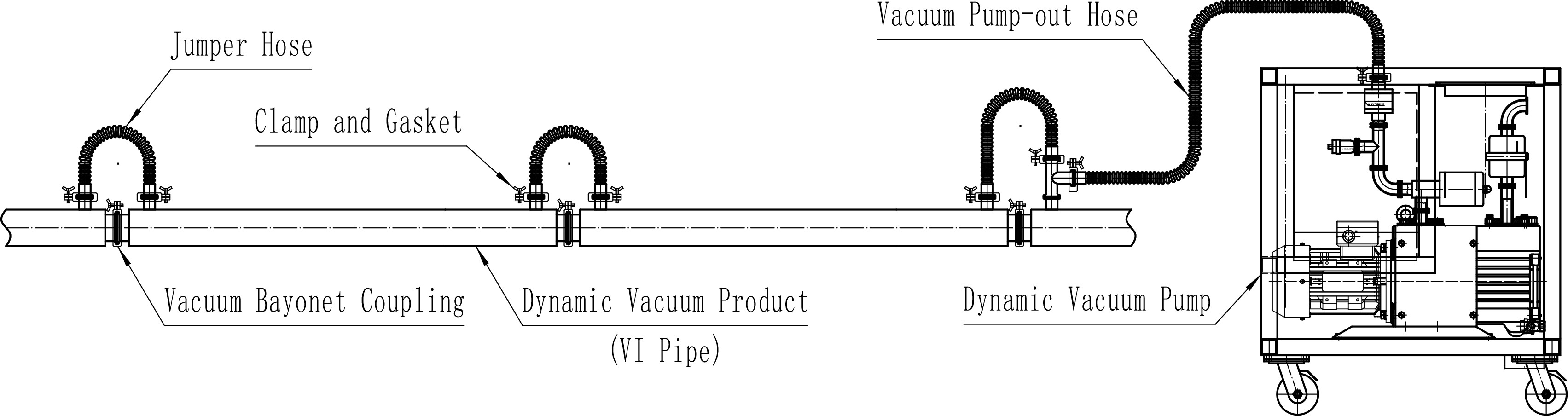

In a Dynamic Vacuum System, vacuum insulated products are installed on-site, and their independent vacuum chambers are interconnected using jumper hoses. These chambers are then linked to one or more vacuum pumps via pump-out hoses. The vacuum pumps continuously maintain a stable vacuum level across the system, ensuring consistent thermal insulation and minimizing cold loss.

This approach contrasts with traditional static systems, where vacuum levels degrade over time, leading to increased cold loss and maintenance needs. Dynamic Vacuum System provides a proactive solution, eliminating the need for secondary vacuum treatments.

Key Advantages of the Dynamic Vacuum System

Superior Thermal Efficiency

DVS maintains a high vacuum level, reducing cold loss and preventing condensation or frost on the surface of VIP products, even in humid environments.

Simplified Maintenance

Unlike static systems, which require periodic re-vacuuming of each VIP product, DVS centralizes maintenance around the vacuum pump. This is especially beneficial in confined or hard-to-access installations.

Long-Term Stability

By continuously regulating vacuum levels, DVS ensures reliable insulation performance over extended periods, making it an ideal choice for critical industrial processes.

Applications of the Dynamic Vacuum System

The Dynamic Vacuum System is widely used in industries such as biopharmaceuticals, electronics, chip manufacturing, and laboratories. Its ability to deliver consistent performance and lower maintenance costs makes it a preferred choice in sectors where precision and reliability are paramount.

Conclusion

The Dynamic Vacuum System represents a significant advancement in the field of vacuum insulated piping. By combining innovative design with practical maintenance advantages, it offers a sustainable solution for industries handling cryogenic fluids. As businesses strive for greater efficiency and cost-effectiveness, DVS is poised to become a standard in VIP applications.

For more information, contact Chengdu Holy Cryogenic Equipment Co., Ltd.

Chengdu Holy Cryogenic Equipment Co., Ltd. :www.hlcryo.com

Post time: Jan-13-2025