What is Vacuum Jacketed Pipe?

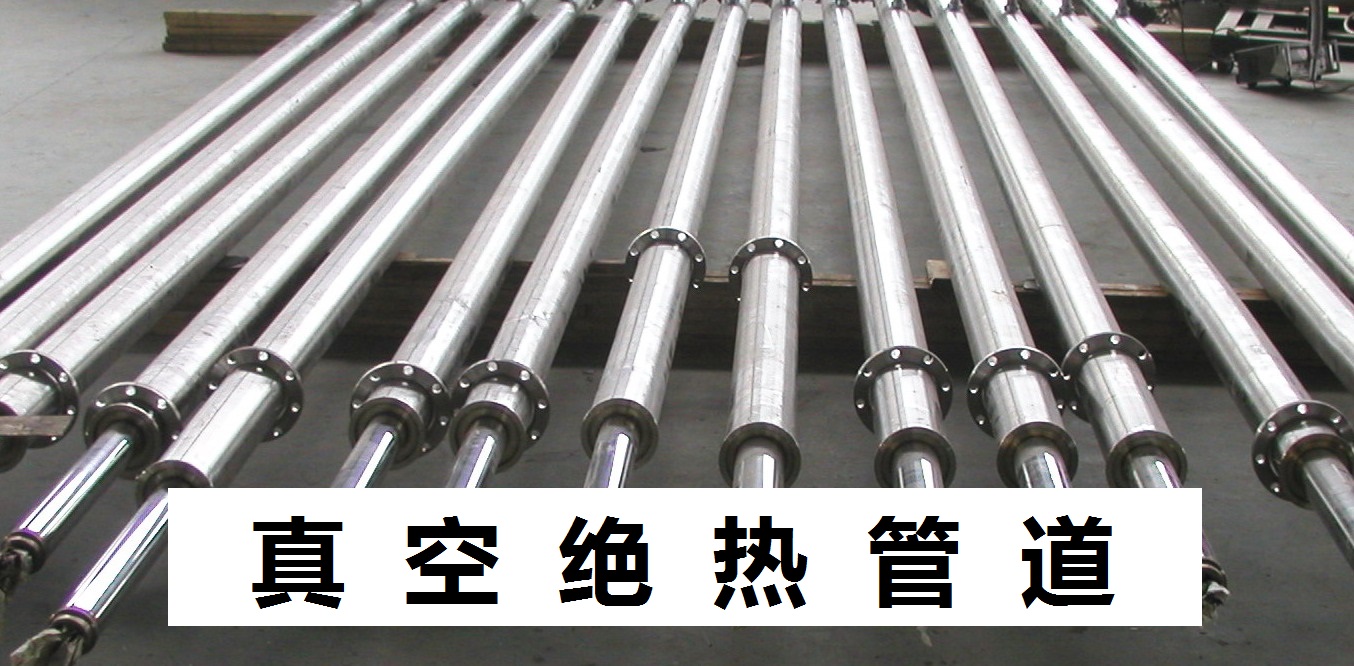

Vacuum Jacketed Pipe (VJP), also known as vacuum insulated piping, is a specialized pipeline system designed for the efficient transportation of cryogenic liquids such as liquid nitrogen, oxygen, argon, and LNG. Through a vacuum-sealed layer between the inner and outer pipes, this structure minimizes heat transfer, reducing liquid boil-off and preserving the integrity of the transported product. This vacuum jacket technology makes VJP an ideal choice for industries that require high-efficiency insulation and reliable performance in handling cryogenic substances.

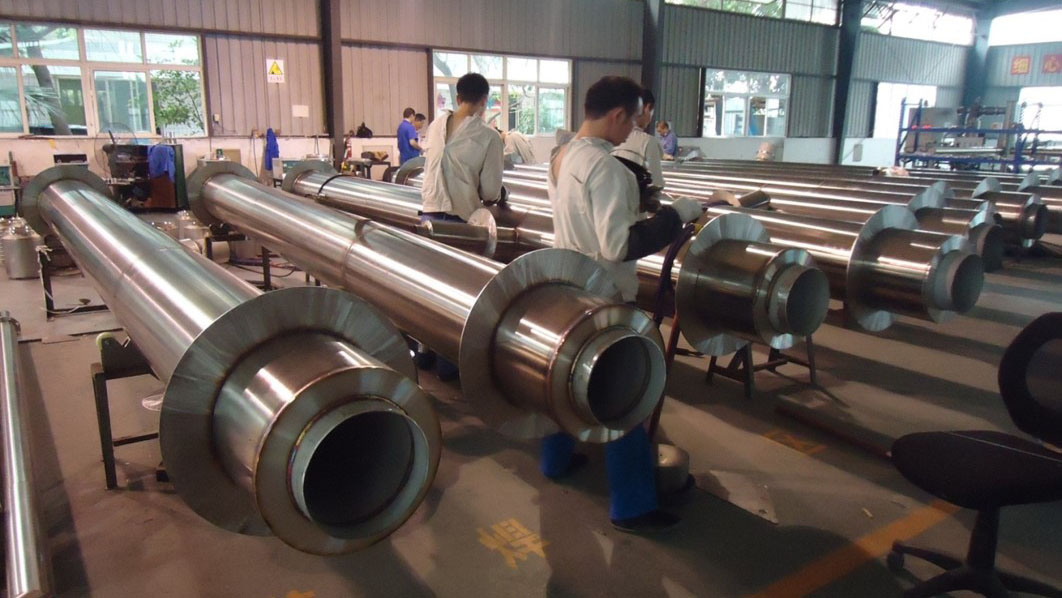

Key Components and Design of Vacuum Jacketed Pipe

The core of a Vacuum Jacketed Pipe lies in its dual-layer design. The inner pipe carries the cryogenic liquid, while an outer jacket, typically stainless steel, surrounds it, with a vacuum between the two layers. This vacuum barrier significantly reduces heat ingress, ensuring that the cryogenic liquid maintains its low temperature throughout transit. Some VJP designs also incorporate multi-layer insulation within the vacuum space, enhancing thermal efficiency even further. These features make Vacuum Jacketed Pipes a critical solution for industries looking to optimize cost-effectiveness and reduce cryogenic liquid loss.

Applications of Vacuum Jacketed Pipe in Industry

Vacuum Jacketed Pipe is widely used in industries such as healthcare, aerospace, and energy, where handling cryogenic liquids safely and efficiently is essential. In medical facilities, VJP systems transport liquid nitrogen for cryopreservation and other applications. The food and beverage industry also relies on VJP to transport liquid gases for food processing and storage. Additionally, VJP plays a crucial role in natural gas processing, where efficient LNG transportation is vital for cost savings and environmental impact reduction.

Why Choose Vacuum Jacketed Pipe?

When it comes to cryogenic liquid transportation, Vacuum Jacketed Pipe stands out for its efficiency and safety. Traditional pipes can lead to significant liquid loss and increased energy consumption due to poor insulation. In contrast, the advanced insulation in VJP systems ensures minimal product loss and operational costs. Choosing Vacuum Jacketed Pipe also enhances safety, as the vacuum insulation reduces the risks associated with cryogenic handling by preventing frost build-up and maintaining stable liquid temperatures.

Future Trends in Vacuum Jacketed Pipe Technology

As technology advances, manufacturers are focusing on improving the efficiency and durability of Vacuum Jacketed Pipes. Emerging trends include enhanced multi-layer insulation, more robust materials, and intelligent monitoring systems that optimize cryogenic fluid flow and temperature. With ongoing research, Vacuum Jacketed Pipe technology is set to play an increasingly critical role in various industries, particularly as the demand for sustainable and energy-efficient solutions grows.

Conclusion

Vacuum Jacketed Pipe offers industries a reliable and efficient solution for transporting cryogenic liquids, with the dual benefits of cost-saving and enhanced safety. By incorporating Vacuum Jacketed Pipe systems, businesses can ensure efficient handling of cryogenic substances while reducing environmental impact. This innovative technology continues to evolve, promising future advancements in the field of cryogenic fluid management.

Post time: Oct-29-2024