Generally, VJ Piping is made of stainless steel including 304, 304L, 316 and 316Letc. Here we will briefly introduce the characteristics of various stainless steel materials.

SS304

304 stainless steel pipe is produced in accordance with the American ASTM standard of a brand of stainless steel.

304 stainless steel pipe is equivalent to our 0Cr19Ni9 (OCr18Ni9) stainless steel pipe.

304 stainless steel tube as stainless steel is most widely used in food equipment, general chemical equipment, and atomic energy industry.

304 stainless steel pipe is a universal stainless steel pipe, it is widely used in the production of good comprehensive performance (corrosion resistance and formability) equipment and parts.

304 stainless steel pipe is the most widely used stainless steel, heat resistant steel. Used in food production equipment, general chemical equipment, nuclear energy, etc.

304 stainless steel tube chemical composition specifications C, Si, Mn, P, S, Cr, Ni, (Nickel), Mo.

Stainless Steel 304 and 304L Performance Difference

304L is more corrosion resistant, 304L contains less carbon, 304 is a universal stainless steel, and it is widely used in the production of equipment and parts requiring good comprehensive performance (corrosion resistance and formability). 304L is a variant of 304 stainless steel with lower carbon content and is used for welding applications. The lower carbon content minimizes carbides precipitation in the heat-affected zone near the weld, which can lead to intergranular corrosion (welding erosion) in stainless steel in some environments.

304 is widely used, with good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Good thermal processing, such as stamping and bending, without heat treatment hardening phenomenon (no magnetic, using temperature -196℃-800℃).

304L has excellent resistance to grain boundary corrosion after welding or stress relief: it can maintain good corrosion resistance even without heat treatment, operating temperature -196℃-800℃.

SS316

316 stainless steel also has good chloride erosion properties, so it is commonly used in Marine environments.

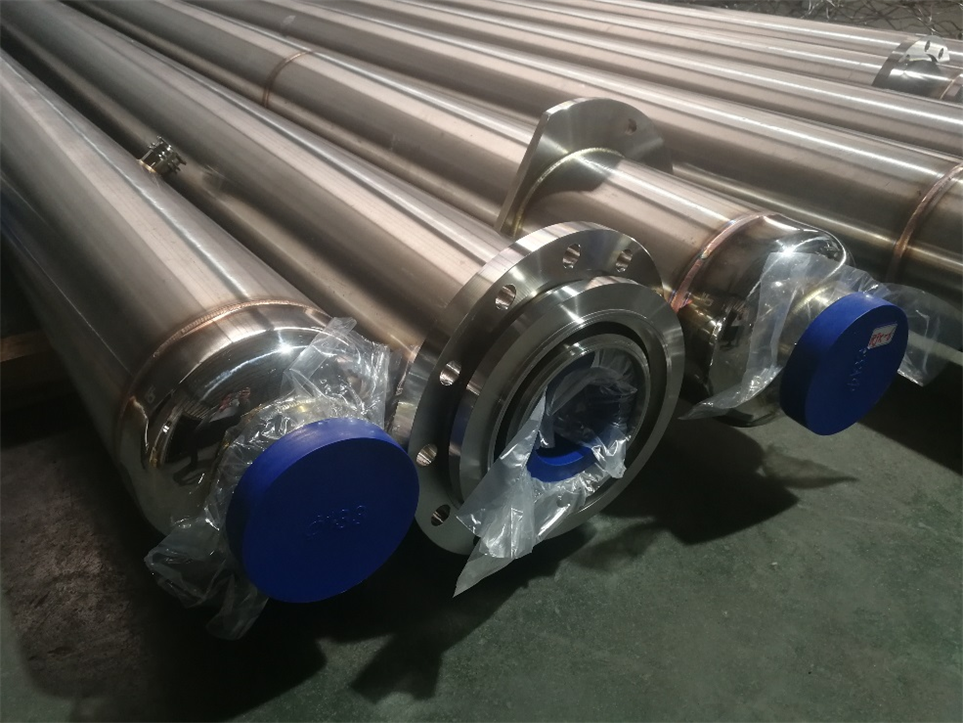

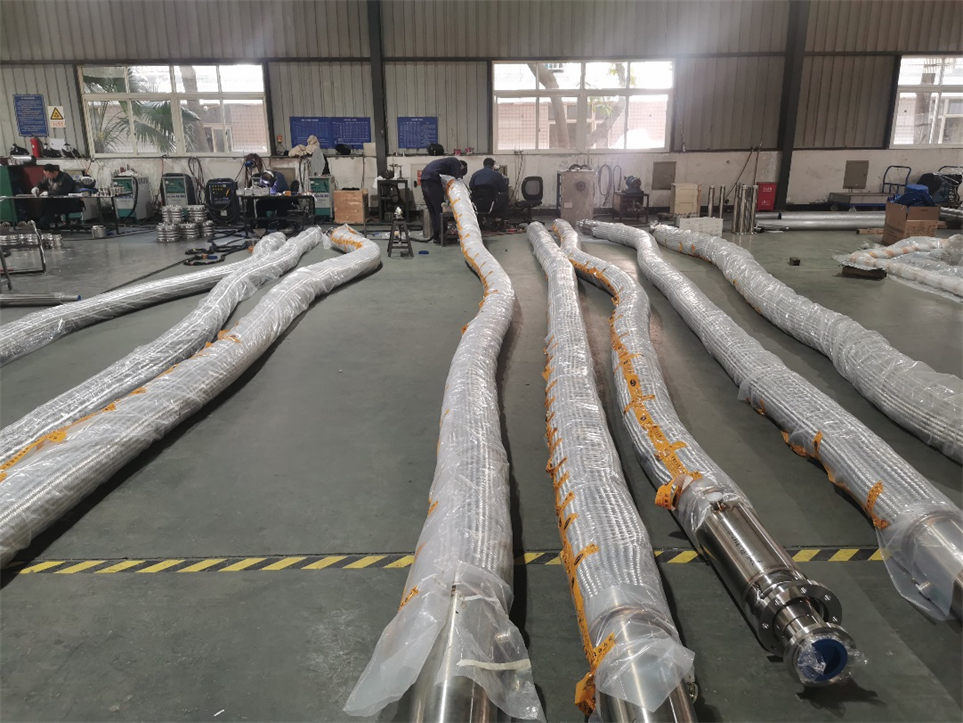

Corrosion resistant stainless steel tube factory

Corrosion resistance is better than 304 stainless steel, in the production process of pulp and paper has good corrosion resistance.

And 316 stainless steel is also resistant to Marine and aggressive industrial atmospheres. Heat resistance in 1600 degrees below the discontinuous use and in 1700 degrees below the continuous use, 316 stainless steel has good oxidation resistance.

In the range of 800-1575 degrees, it is best not to continuously use 316 stainless steel, but in the temperature range outside the continuous use of 316 stainless steel, the stainless steel has good heat resistance.

The carbide precipitation resistance of 316 stainless steel is better than that of 316 stainless steel and can be used in the above temperature range.

316 stainless steel has good welding performance. Can be welded using all standard welding methods. Welding can be used according to the use of 316Cb, 316L or 309CB stainless steel filler rod or electrode welding. In order to obtain the best corrosion resistance, the welded section of 316 stainless steel shall be annealed after welding. Post weld annealing is not required if 316L stainless steel is used.

Typical uses: pulp and paper equipment heat exchangers, dyeing equipment, film developing equipment, pipelines, and materials for the exterior of urban buildings in coastal areas.

Antibacterial Stainless Steel

With the development of economy, the stainless steel in the food industry, catering services and the application of family life is more and more widely, it is hoped that besides stainless steel household utensils and tableware, bright and clean as new features, but also has the best mildew, antibacterial, the sterilization function.

As we all know, some metals, such as silver, copper, bismuth and so on have antibacterial, bactericidal effect, the so-called antibacterial stainless steel, is in stainless steel to add the right amount of elements with antibacterial effect (such as copper, silver), the production of steel after antibacterial heat treatment, with stable processing performance and good antibacterial performance.

Copper is the key element of antibacterial, how much to add should not only consider antibacterial property, but also ensure good and stable processing properties of steel. The optimum amount of copper varies with steel types. Chemical composition of antibacterial stainless steel developed by Japanese Nissin Steel is shown in Table 10. 1.5% copper is added to ferritic steel, 3% to martensitic steel and 3.8% to austenitic steel.

Post time: Jan-05-2022