Vacuum insulated pipe (VIP) is a critical component in transporting cryogenic liquids, such as liquefied natural gas (LNG), liquid hydrogen (LH2), and liquid nitrogen (LN2). The challenge of keeping these liquids at extremely low temperatures without significant heat transfer is solved using vacuum insulation technology. This blog will explain how vacuum insulated pipe provides thermal insulation and its significance in industries that rely on cryogenic systems.

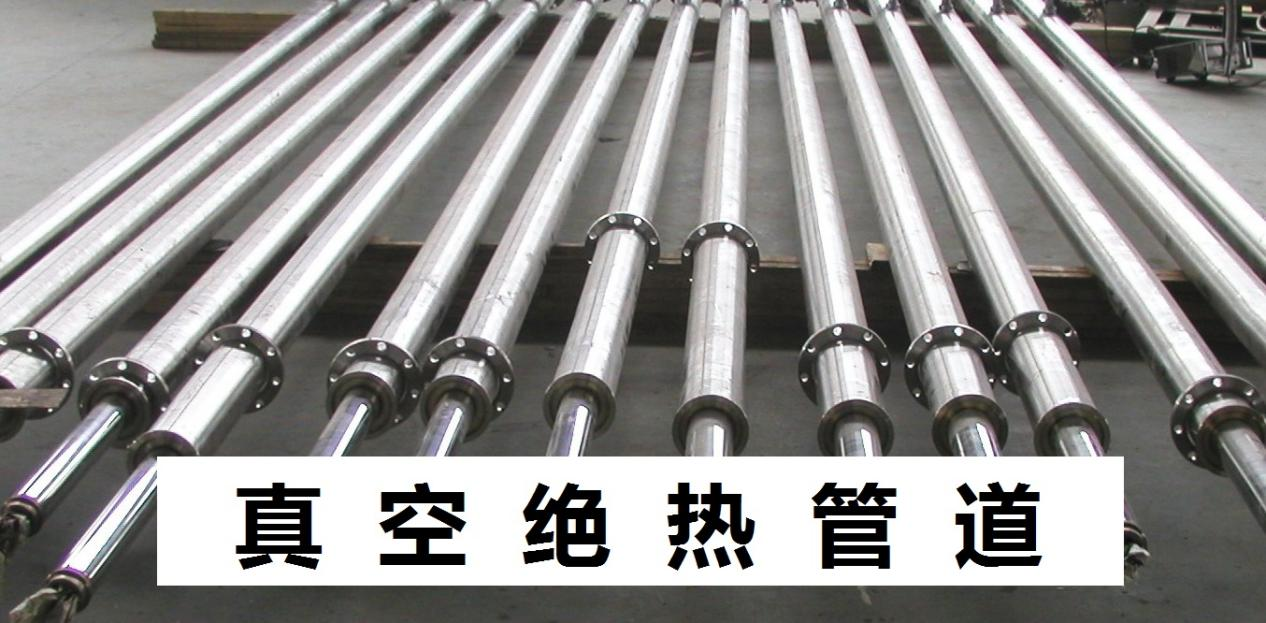

What Is a Vacuum Insulated Pipe?

A vacuum insulated pipe consists of two concentric pipes: an inner pipe that carries the cryogenic liquid and an outer pipe that encloses the inner pipe. The space between these two pipes is evacuated to create a vacuum, which acts as a highly effective thermal insulator. The vacuum minimizes heat transfer via conduction and convection, which helps maintain the liquid at its required low temperature.

How Vacuum Insulation Works

The key to the thermal efficiency of a vacuum insulated pipe is the vacuum layer. Heat transfer typically occurs through three main processes: conduction, convection, and radiation. The vacuum eliminates conduction and convection because there are no air molecules in the space between the pipes to transfer heat. In addition to the vacuum, the pipe often incorporates reflective shielding inside the vacuum space, reducing heat transfer via radiation.

Why Vacuum Insulated Pipe Is Crucial for Cryogenic Systems

Cryogenic liquids are sensitive to even small increases in temperature, which can cause them to vaporize, leading to product loss and potential hazards. Vacuum insulated pipe ensures that the temperature of cryogenic fluids like LNG, LH2, or LN2 remains stable during transportation. This significantly reduces boil-off gas (BOG) formation, maintaining the liquid in its desired state for extended periods.

Applications of Vacuum Insulated Pipe

Vacuum insulated pipe is used in various industries, including energy, aerospace, and medical fields. In the LNG industry, VIPs are employed to transfer liquefied natural gas between storage tanks and terminals with minimal thermal loss. In the aerospace sector, VIPs ensure the safe transfer of liquid hydrogen, crucial for rocket propulsion. Similarly, in healthcare, liquid nitrogen is transported using VIPs to preserve biological materials and support medical applications.

Conclusion: The Efficiency of Vacuum Insulated Pipe

The role of vacuum insulated pipe in cryogenic liquid transportation cannot be overstated. By minimizing heat transfer through advanced insulation methods, VIPs ensure the safe and efficient transport of cryogenic liquids, making them essential for industries that depend on low-temperature technologies. As the demand for cryogenic applications grows, the importance of vacuum insulated pipes will continue to rise, ensuring thermal efficiency and safety in critical operations.

Post time: Oct-10-2024