In the fast-paced semiconductor industry, maintaining precise environmental conditions is crucial for high-quality manufacturing processes. Molecular Beam Epitaxy (MBE), a pivotal technique in semiconductor fabrication, significantly benefits from advancements in cooling technology, particularly through the use of liquid nitrogen and vacuum insulated pipes (VIP). This blog explores the critical role of VIP in enhancing MBE applications, emphasizing its efficiency and reliability.

The Importance of Cooling in MBE

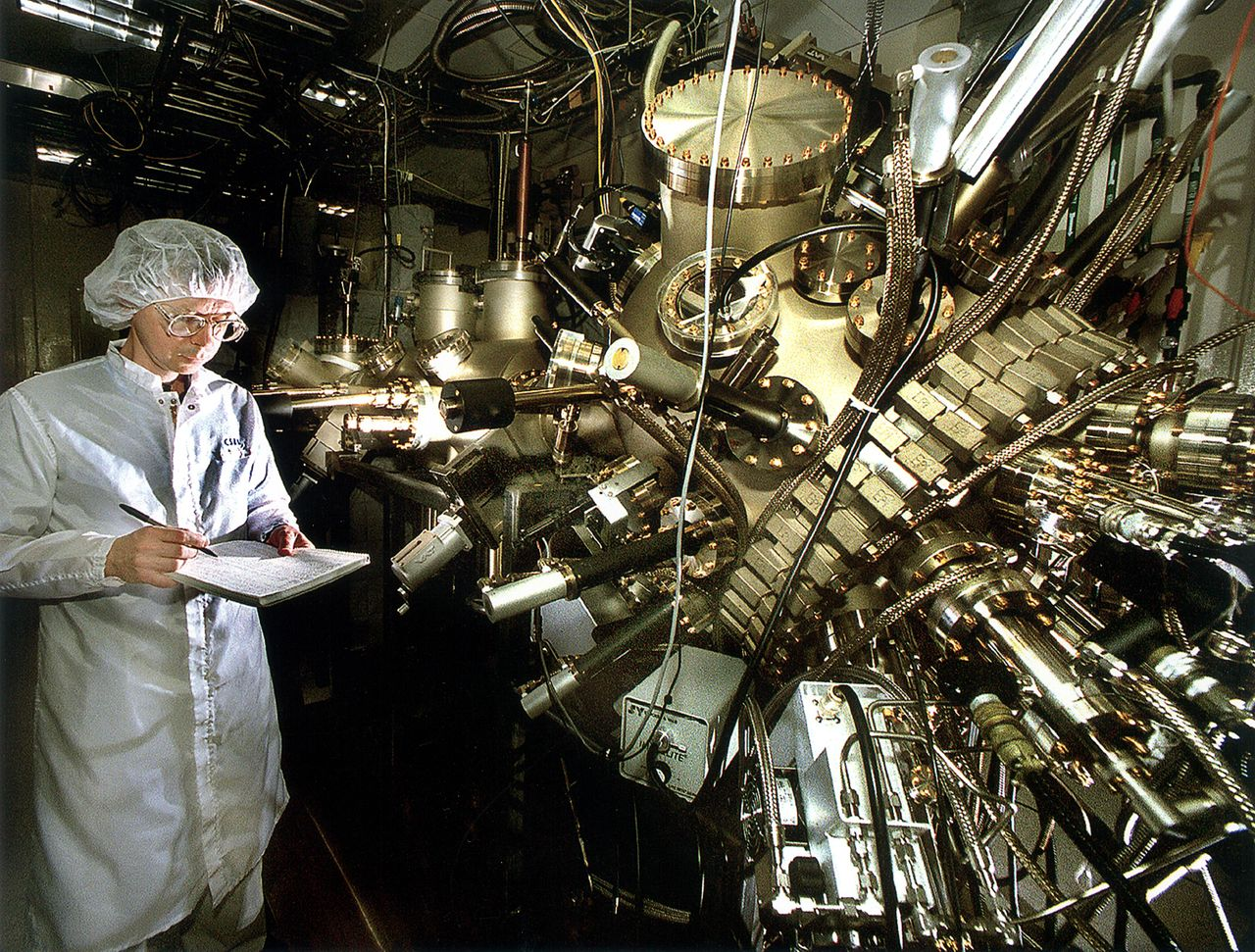

Molecular Beam Epitaxy (MBE) is a highly controlled method of depositing atomic layers on a substrate, essential for producing semiconductor devices like transistors, lasers, and solar cells. To achieve the high precision required in MBE, maintaining stable low temperatures is vital. Liquid nitrogen is often used for this purpose due to its extremely low boiling point of -196°C, ensuring that the substrates remain at the necessary temperatures during the deposition process.

The Role of Liquid Nitrogen in MBE

Liquid nitrogen is indispensable in MBE processes, providing a consistent cooling mechanism that ensures the deposition occurs without unwanted thermal fluctuations. This stability is crucial for producing high-quality semiconductor materials, as even minor temperature variations can lead to defects or inconsistencies in the atomic layers. The use of liquid nitrogen helps to achieve the ultra-high vacuum conditions required for MBE, preventing contamination and ensuring the purity of the materials.

Advantages of Vacuum Insulated Pipes (VIP) in MBE

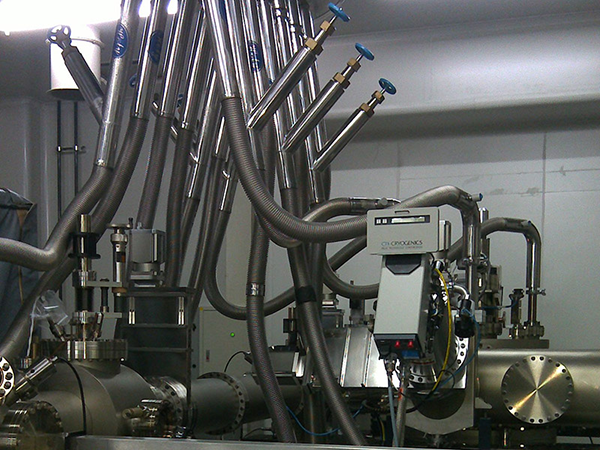

Vacuum insulated pipes (VIP) are a breakthrough in the efficient transport of liquid nitrogen. These pipes are designed with a vacuum layer between two walls, significantly reducing heat transfer and maintaining the cryogenic temperature of liquid nitrogen as it travels from storage to the MBE system. This design minimizes the loss of liquid nitrogen due to evaporation, ensuring a steady and reliable supply to the MBE apparatus.

Efficiency and Cost-Effectiveness

Using VIP in MBE applications offers several advantages. The reduced heat loss means less liquid nitrogen is required, lowering operational costs and enhancing efficiency. Additionally, the insulation properties of VIP contribute to a safer working environment by minimizing the risk of frostbite and other hazards associated with handling cryogenic materials.

Enhanced Process Stability

VIP ensures that the liquid nitrogen remains at a consistent temperature throughout its journey to the MBE system. This stability is paramount for maintaining the stringent conditions necessary for high-precision semiconductor manufacturing. By preventing temperature fluctuations, VIP helps to produce more uniform and defect-free semiconductor layers, enhancing the overall quality and performance of the final products.

HL Cryogenic Equipment: Leading the Way with Advanced Liquid Nitrogen Circulation Systems

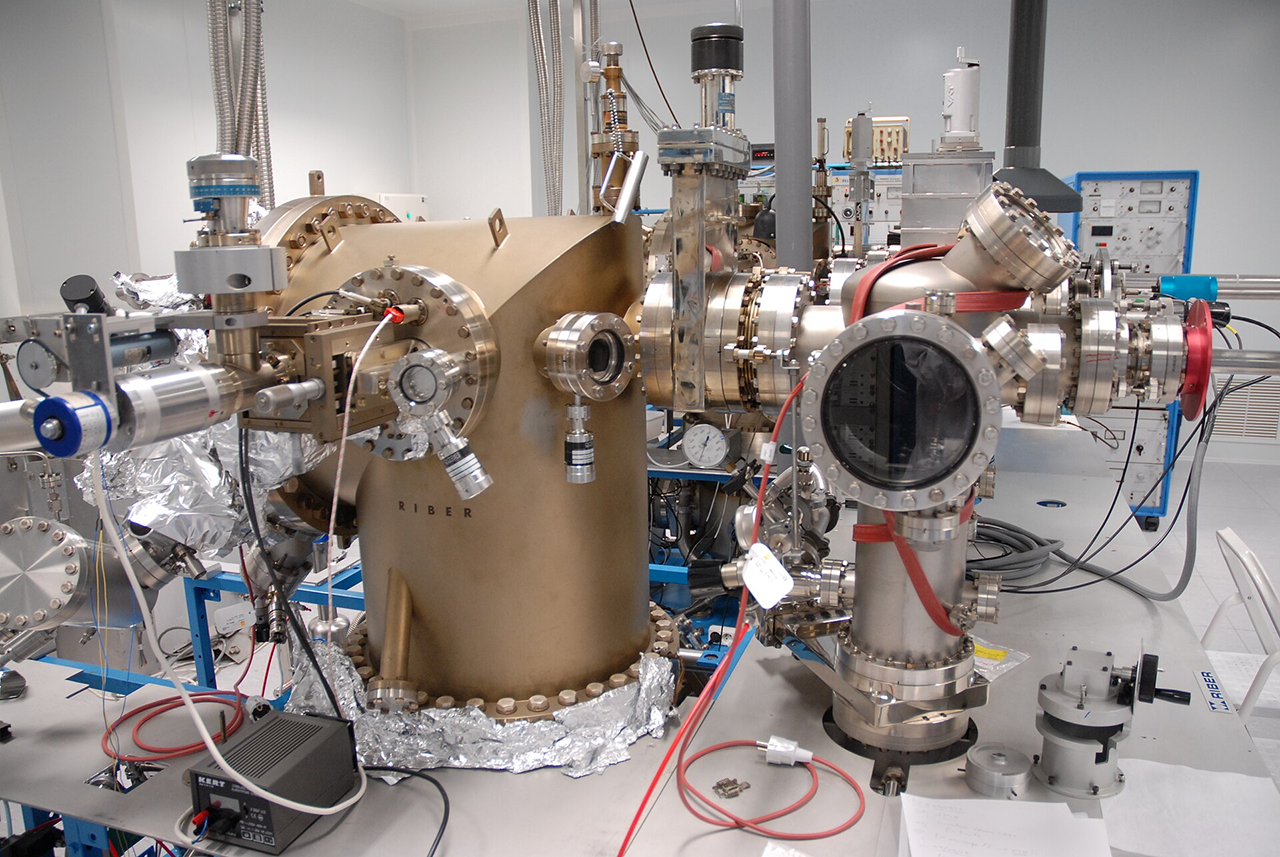

HL Cryogenic Equipment Co., Ltd has developed and researched a state-of-the-art Liquid Nitrogen Transport Circulation System that starts from the storage tank and ends with the MBE equipment. This system realizes the functions of liquid nitrogen transportation, impurity discharge, pressure reduction & regulation, nitrogen discharge, and recycling. The entire process is monitored by cryogenic sensors and controlled by a PLC, enabling the switch between automatic and manual operation modes.

Currently, this system is stably operating MBE equipment from leading manufacturers such as DCA, RIBER, and FERMI. The incorporation of HL Cryogenic Equipment's advanced system ensures a reliable and efficient supply of liquid nitrogen, further enhancing the performance and stability of MBE processes.

Conclusion

In the semiconductor industry, particularly in MBE applications, the use of liquid nitrogen and vacuum insulated pipes (VIP) is indispensable. VIP not only enhances the efficiency and cost-effectiveness of cooling systems but also ensures the stability and precision required for high-quality semiconductor fabrication. As the demand for advanced semiconductor devices continues to grow, innovations in VIP technology and advanced systems like those developed by HL Cryogenic Equipment will play a critical role in meeting the industry's stringent requirements and driving future advancements.

By leveraging the benefits of VIP and HL Cryogenic Equipment's sophisticated Liquid Nitrogen Transport Circulation System, semiconductor manufacturers can achieve greater consistency, efficiency, and safety in their MBE processes, ultimately contributing to the development of next-generation electronic devices.

Post time: Jun-15-2024