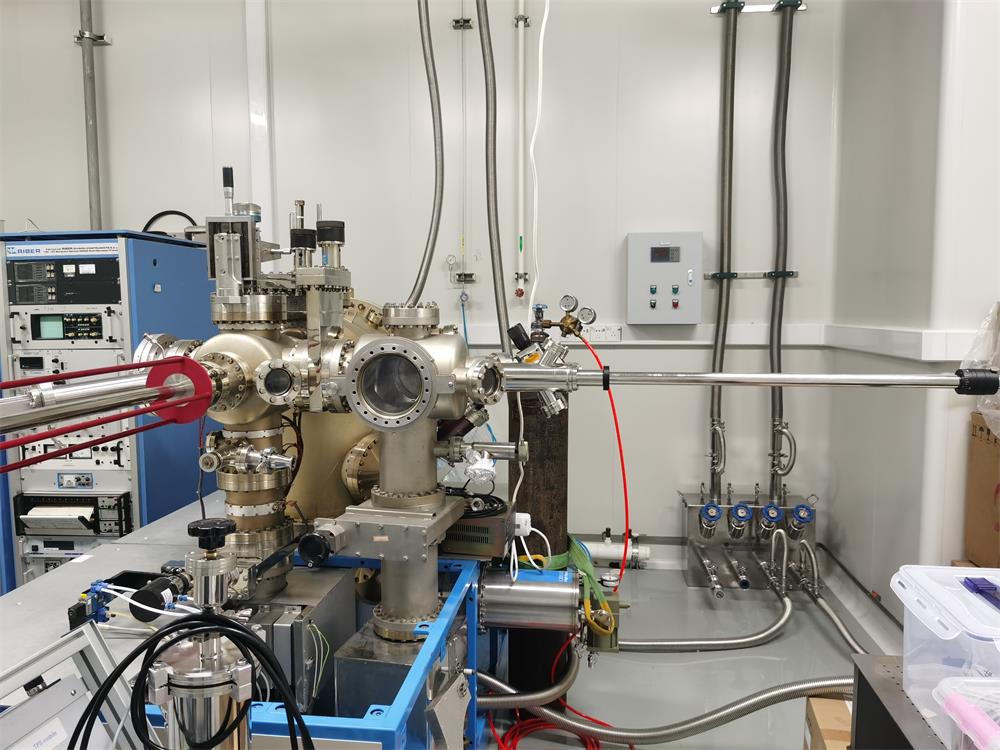

Molecular Beam Epitaxy technology was developed by Bell Laboratories in the early 1970s on the basis of vacuum deposition method and Arthur's study on the reaction kinetics of gallium as atom interaction with GaAs surface in 1968. It promotes the development of a new generation of semiconductor science and technology based on ultrathin layer microstructure materials. Molecular beam epitaxy (MBE) is a flexible epitaxy thin film technology, which can be expressed as generating high quality thin film materials or various required structures by projecting the atoms or molecular beams generated by thermal evaporation onto a clean substrate with a certain orientation and temperature in ultra-high vacuum environment.

Molecular beam epitaxy (MBE) system market size analysis

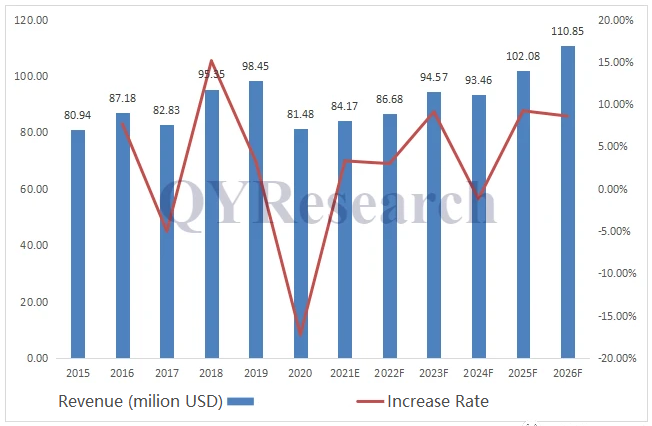

Molecular beam epitaxial system is an important equipment for semiconductor and photovoltaic new materials and process research. The global market size of molecular beam epitaxial system reached USD 81.48 million in 2020, and is expected to reach USD 111 million in 2026, with a compound annual growth rate (CAGR) of 5.26%.

Europe is currently the world's largest production area of the cluster epitomized system, and exports to many countries in the world, which are mainly imported by imports, although there are a small number of manufacturers with production capacity, but the product is inadequate and urgently needs to improve the value of the product to capture the market. At the same time, with the development of semiconductor and material industry, the customer has put forward more quality requirements and higher technical indicators as the key research and the molecular beam epitaxy system of the production equipment, and the change in specification is becoming more and more diverse. The molecular beam epitaxial system enterprise should actively improve the quality of the product, thereby making its products attractive.

The major molecular coepitaxial system manufacturers in the market include American veecoc, riber and Finland dca, and the common type of molecular fastipron products are more products, such as veeco, riber and sienta omicron, etc. The laser molecular beam epitaxial system manufacturer mainly includes Japan pascaly, the Netherlands TSST, etc. At present, the common type molecular beam epitaxial system is the main sales market, the market share is about 73%, the laser molecular beam epitaxial system is widely used because of the film that is suitable for the growth of polyelement, high melting point and complex layer structure.

The molecular beam epitaxy system is mainly used in the research of semiconductor and basic materials. The main consumer of the cluster epitaxy system is a country with a more complete industrial system, such as Europe, the United States, Japan and China, which account for more than 80 percent of the world's market. At the same time, developing countries such as India, Southeast Asia and other recent years have also gradually stepped up investment in basic research fields, and the future will have greater market potential.

The global spread of the global economy has been in part due to the development of the world economy and semiconductor, which is difficult to guarantee in the enterprise's capacity and downstream market, which has also led to a certain difficulty in the production of the group of microexpanses, such as the decline of the company's sales in the first half of the year in the first half of the year, so the enterprise needs to maintain sufficient cash flow to cope with the development of the outbreak. Although external environment and industry competition problems exist, we believe that the market outlook of the bank industry is still a certain development prospect, and the investment of the industry will continue to increase.

MBE Liquid Nitrogen Cooling Circulation System

MBE equipment needs to be high and fast, so the chamber needs to be cooled. HL has a full range of mature liquid nitrogen cooling circulation system solutions.

The liquid nitrogen cooled circulation system contains, vacuum insulated (VI) pipes, VI flexible hoses, VI valves, VI circulation phase separator etc.

HL Cryogenic Equipment

HL Cryogenic Equipment which was founded in 1992 is a brand affiliated to Chengdu Holy Cryogenic Equipment Company in China. HL Cryogenic Equipment is committed to the design and manufacture of the High Vacuum Insulated Cryogenic Piping System and related Support Equipment.

For more information, please visit the official website www.hlcryo.com, or email to info@cdholy.com.

Post time: Jul-20-2022