The food industry is constantly evolving, driven by advancements in technology that enhance efficiency and sustainability. One such innovation making significant waves is the Vacuum Insulated Pipe (VIP). This cutting-edge solution is redefining how the food industry manages temperature-sensitive processes, offering unparalleled thermal insulation and energy savings.

Introduction to Vacuum Insulated Pipe (VIP)

Vacuum Insulated Pipes (VIPs) are specialized piping systems designed to minimize heat transfer. By creating a vacuum between the inner and outer pipes, VIPs provide exceptional insulation, which is crucial for maintaining specific temperatures in various industrial processes. In the food industry, where temperature control is paramount, VIPs are becoming indispensable.

Enhancing Temperature Control in Food Processing

One of the primary applications of Vacuum Insulated Pipe (VIP) in the food industry is in processing and manufacturing facilities. Maintaining the right temperature is critical to ensuring the quality and safety of food products. VIPs are used to transport hot and cold fluids with minimal heat loss or gain, ensuring consistent temperatures throughout the production process. This precision helps in maintaining the integrity of ingredients and finished products, reducing the risk of spoilage and contamination.

HL Cryogenic Equipment's Leading Technology

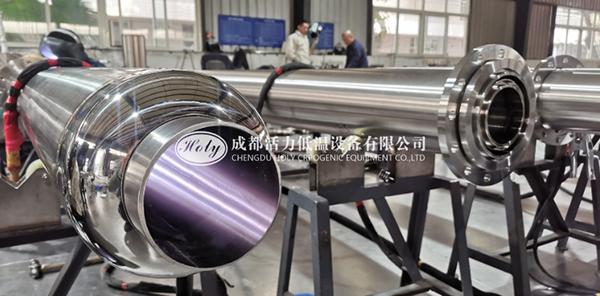

HL Cryogenic Equipment is at the forefront of Vacuum Insulated Pipe (VIP) technology. As a renowned manufacturer of high-quality cryogenic equipment, HL Cryogenic Equipment offers VIP products known for their superior performance and reliability. The company's vacuum insulated piping systems are widely used across various industries, especially in the food sector, helping businesses achieve efficient temperature control and energy savings.

HL Cryogenic Equipment's VIP products are designed and manufactured using advanced techniques to ensure optimal insulation and durability. By partnering with HL Cryogenic Equipment, food industry enterprises can obtain customized solutions tailored to their specific needs and challenges. These solutions not only enhance production efficiency but also significantly reduce energy costs, boosting overall competitiveness.

Energy Efficiency and Cost Savings

Energy consumption is a significant concern for the food industry, given the extensive use of heating and cooling systems. Vacuum Insulated Pipe (VIP) technology offers remarkable energy efficiency by significantly reducing thermal losses. This efficiency translates to lower energy consumption, leading to substantial cost savings. Food manufacturers can thus achieve more sustainable operations while enjoying reduced utility bills.

Applications in Food Storage and Transportation

In addition to processing facilities, Vacuum Insulated Pipes (VIPs) are also crucial in food storage and transportation. Cold storage warehouses and refrigerated transport vehicles benefit immensely from VIP technology. By maintaining stable temperatures, VIPs ensure that perishable goods are stored and transported under optimal conditions, preserving freshness and extending shelf life. This capability is particularly important for the global distribution of temperature-sensitive products like dairy, meat, and fresh produce.

Improving Sustainability in the Food Industry

Sustainability is a growing priority for the food industry, and Vacuum Insulated Pipe (VIP) systems contribute significantly to this goal. By enhancing energy efficiency and reducing carbon footprints, VIPs help food companies align with environmental regulations and consumer expectations for greener practices. The use of VIPs can lead to a substantial reduction in greenhouse gas emissions, supporting the industry’s shift towards more sustainable operations.

Future Prospects of VIP in the Food Sector

The adoption of Vacuum Insulated Pipe (VIP) technology is poised to grow as the food industry continues to prioritize efficiency and sustainability. Innovations in VIP design and materials promise even greater thermal performance and durability, making them an integral component of modern food processing and distribution systems. As more companies recognize the benefits, VIPs are set to become a standard in the industry.

Conclusion

Vacuum Insulated Pipe (VIP) technology is transforming the food industry by enhancing temperature control, improving energy efficiency, and supporting sustainability initiatives. As the demand for high-quality, safe, and sustainable food products grows, VIPs will play a crucial role in meeting these challenges. HL Cryogenic Equipment, with its superior VIP products, provides reliable and efficient solutions for the food industry. Embracing this advanced piping solution is a strategic move for food manufacturers aiming to stay competitive and responsible in a rapidly changing market.

Post time: Jun-24-2024