Vacuum insulated pipe (VIP) plays a crucial role in various high-tech fields, particularly in molecular beam epitaxy (MBE) systems. MBE is a technique used to create high-quality semiconductor crystals, a critical process in modern electronics, including semiconductor devices, laser technology, and advanced materials. Maintaining ultra-low temperatures during these processes is essential, and vacuum insulated pipe technology ensures the efficient transport of cryogenic liquids to maintain those necessary conditions. This blog will explore the role and significance of vacuum insulated pipe in MBE systems.

What Is Molecular Beam Epitaxy (MBE)?

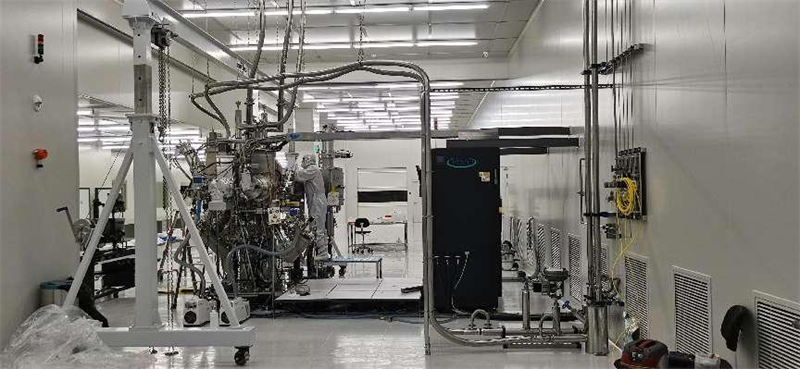

Molecular beam epitaxy (MBE) is a highly controlled process for growing thin films of materials, often used in the production of semiconductors. The process takes place in a high vacuum environment, where beams of atoms or molecules are directed onto a substrate, allowing for layer-by-layer growth of crystals with precise control. To maintain the integrity of this process, extremely low temperatures are required, which is where vacuum insulated pipe technology becomes essential.

The Role of Vacuum Insulated Pipe in MBE Systems

Vacuum insulated pipe is used in MBE systems to transport cryogenic liquids, such as liquid nitrogen or liquid helium, to cool components within the system. These cryogenic liquids are crucial for maintaining the ultra-high vacuum and temperature control that MBE systems require for optimal performance. Without effective insulation, the cryogenic liquids would warm up quickly, resulting in temperature instability and compromising the quality of the epitaxial growth.

The vacuum insulated pipe ensures minimal thermal losses during the transport of these cryogenic fluids. The vacuum layer between the inner and outer pipes acts as a highly efficient insulator, reducing heat transfer via conduction and convection, which are the primary causes of temperature fluctuations in cryogenic systems.

Why Vacuum Insulated Pipe Is Essential for MBE Systems

The high precision required in MBE systems makes vacuum insulated pipe a necessity. VIP technology reduces the risk of cryogenic liquid boil-off, which can disrupt the system’s cooling and vacuum stability. Additionally, the use of vacuum insulated pipes helps reduce energy costs by minimizing the need for additional cooling power, enhancing the system’s overall efficiency.

Another advantage of using vacuum insulated pipe in MBE systems is its long-term reliability. The pipes are designed to maintain thermal insulation over extended periods, ensuring consistent performance in highly sensitive environments like MBE.

Conclusion: Vacuum Insulated Pipe Enhances MBE System Performance

The integration of vacuum insulated pipe in MBE systems is crucial for maintaining the high precision and stability these processes demand. By minimizing heat transfer, VIP technology ensures that cryogenic liquids stay at the required low temperatures, promoting optimal semiconductor growth and reducing operational costs. As MBE technology continues to advance, the role of vacuum insulated pipe in supporting these processes will remain indispensable.

Post time: Oct-11-2024