Understanding Vacuum Jacketed Pipe Technology

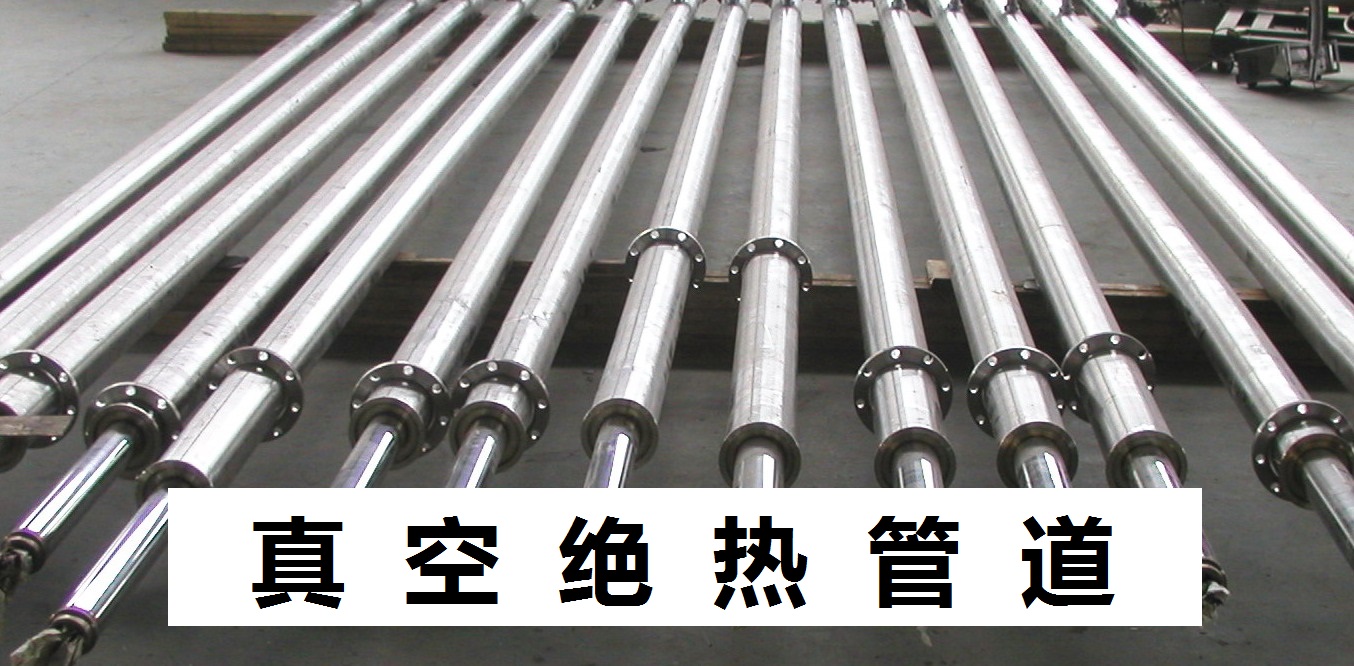

Vacuum Jacketed Pipe, also referred to as Vacuum Insulated Pipe (VIP), is a highly specialized piping system designed to transport cryogenic liquids like liquid nitrogen, oxygen, and natural gas. Utilizing a vacuum-sealed space between the inner and outer pipes, this technology effectively minimizes heat transfer, ensuring the cryogenic liquid remains stable over long distances. The design of Vacuum Jacketed Pipe not only enhances thermal efficiency but also reduces energy consumption, making it an essential tool for industries that prioritize sustainability and cost-effectiveness.

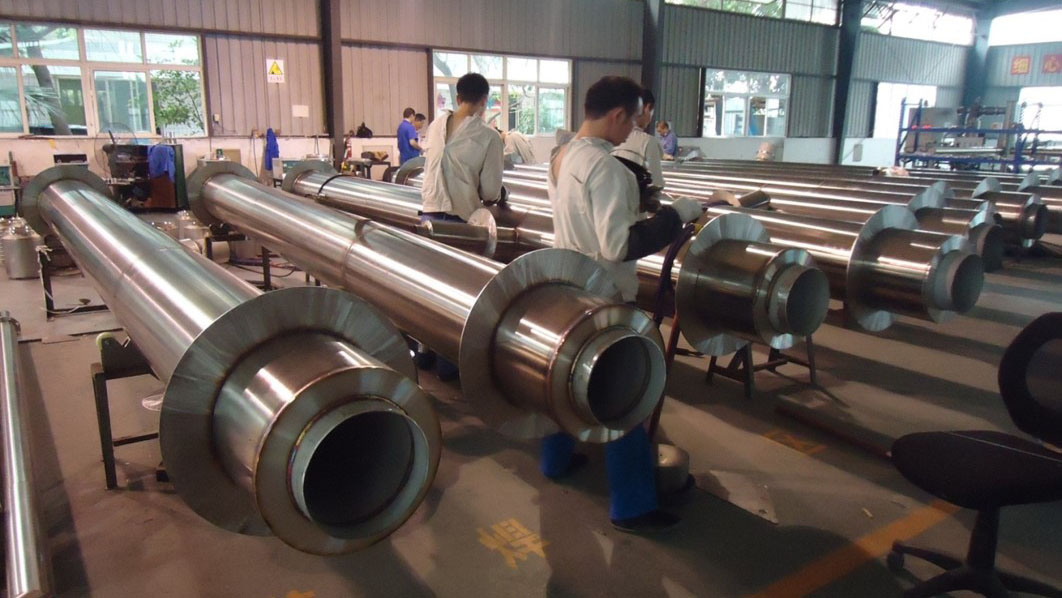

Structure and Features of Vacuum Insulated Pipe

A Vacuum Insulated Pipe is constructed with two primary layers: an inner stainless steel pipe for cryogenic fluid transport and an outer jacket that encloses it. Between these layers is a high-quality vacuum insulation layer, which prevents ambient heat from entering the system and causing liquid evaporation or boil-off. To further improve insulation, the vacuum space may be filled with multi-layer insulation or reflective materials. These innovations in Vacuum Jacketed Pipe design are crucial in cryogenic industries where the slightest temperature fluctuation can impact product quality and efficiency.

Applications of Vacuum Jacketed Pipe Across Industries

The versatility of Vacuum Jacketed Pipe technology extends to many sectors. In healthcare, Vacuum Insulated Pipes are commonly used to transport liquid nitrogen and oxygen for storage and cryotherapy. In the food and beverage industry, they facilitate the safe transfer of cryogenic gases used in rapid freezing processes. Additionally, Vacuum Jacketed Pipes are widely employed in energy sectors, particularly in natural gas and LNG transport, where they provide a reliable solution for moving cryogenic substances without significant temperature loss. This technology has also found applications in aerospace and research laboratories, where precise temperature control is critical.

Advantages of Using Vacuum Jacketed Pipe

Vacuum Jacketed Pipe systems offer significant advantages over conventional insulated pipes. Due to their vacuum-sealed insulation, these pipes experience minimal thermal conductivity, which prevents frost buildup and ensures consistent liquid flow. This not only minimizes product loss but also contributes to reduced operational costs. Another key advantage of Vacuum Insulated Pipe is enhanced safety; by maintaining cryogenic temperatures and preventing outer surface freezing, VJP systems reduce handling risks and simplify maintenance.

Future Developments in Vacuum Insulated Pipe Technology

As the demand for energy-efficient and sustainable solutions grows, the Vacuum Insulated Pipe industry is evolving. New developments focus on advanced insulation materials, durability, and automated systems that monitor and optimize fluid flow and temperature. With the potential for reduced emissions and minimized energy use, Vacuum Jacketed Pipe technology is positioned to support the future of energy-efficient transportation and cryogenic processing.

Conclusion

Vacuum Jacketed Pipe (Vacuum Insulated Pipe) represents a high-performance solution for industries that rely on cryogenic liquid transport. Its advanced insulation, efficiency, and safety benefits make it an industry standard for many sectors. With innovations continuing to improve the technology, Vacuum Jacketed Pipe will play an increasingly important role in sustainable industrial applications, offering both environmental and operational benefits.

Post time: Oct-30-2024