Vacuum insulated pipe is used for conveying low temperature medium, and has the special effect of cold insulation pipe. The insulation of vacuum insulated pipe is relative. Compared with the traditional insulated treatment, the vacuum insulation is more effective.

How to determine whether the vacuum insulated pipe is in effective working condition during its long-term use? Mainly by observing whether the outer wall of the VI pipe appears the phenomenon of water and frost. (If the vacuum insulation tube is equipped with a vacuum gauge, the vacuum degree can be read.) Usually, we say that the phenomenon of water and frost forming on the outer wall of the VI pipe is that the vacuum degree is insufficient, and it cannot continue to effectively play the insulated role.

Causes of the Phenomenon of Water Condensation and Frosting

There are usually two causes of frosting,

● Vacuum nozzle or welds leak, resulting in a decrease in vacuum.

● The natural release of gas from the material causes a decrease in vacuum.

Vacuum nozzle or weld leaks, which belong to unqualified products. Manufacturers lack effective inspection equipment and inspection system in inspection. Vacuum insulation products made by excellent manufacturers usually do not have problems in this regard after delivery.

The material releases gas, which is unavoidable. In the long-term use of VI pipe, stainless steel and insulated materials will continue to release gas in the vacuum interlayer, gradually reduce the vacuum degree of the vacuum interlayer. So the VI pipe has a certain service life. When the vacuum degree drops to the state that cannot be adiabatic, the VI pipe can be vacuumed for the second time through the pumping unit to improve the vacuum degree and restore its insulated effect.

Frosting is not enough vacuum, and so is water?

When the phenomenon of water formation occurs in the vacuum adiabatic tube, the vacuum degree is not necessarily insufficient.

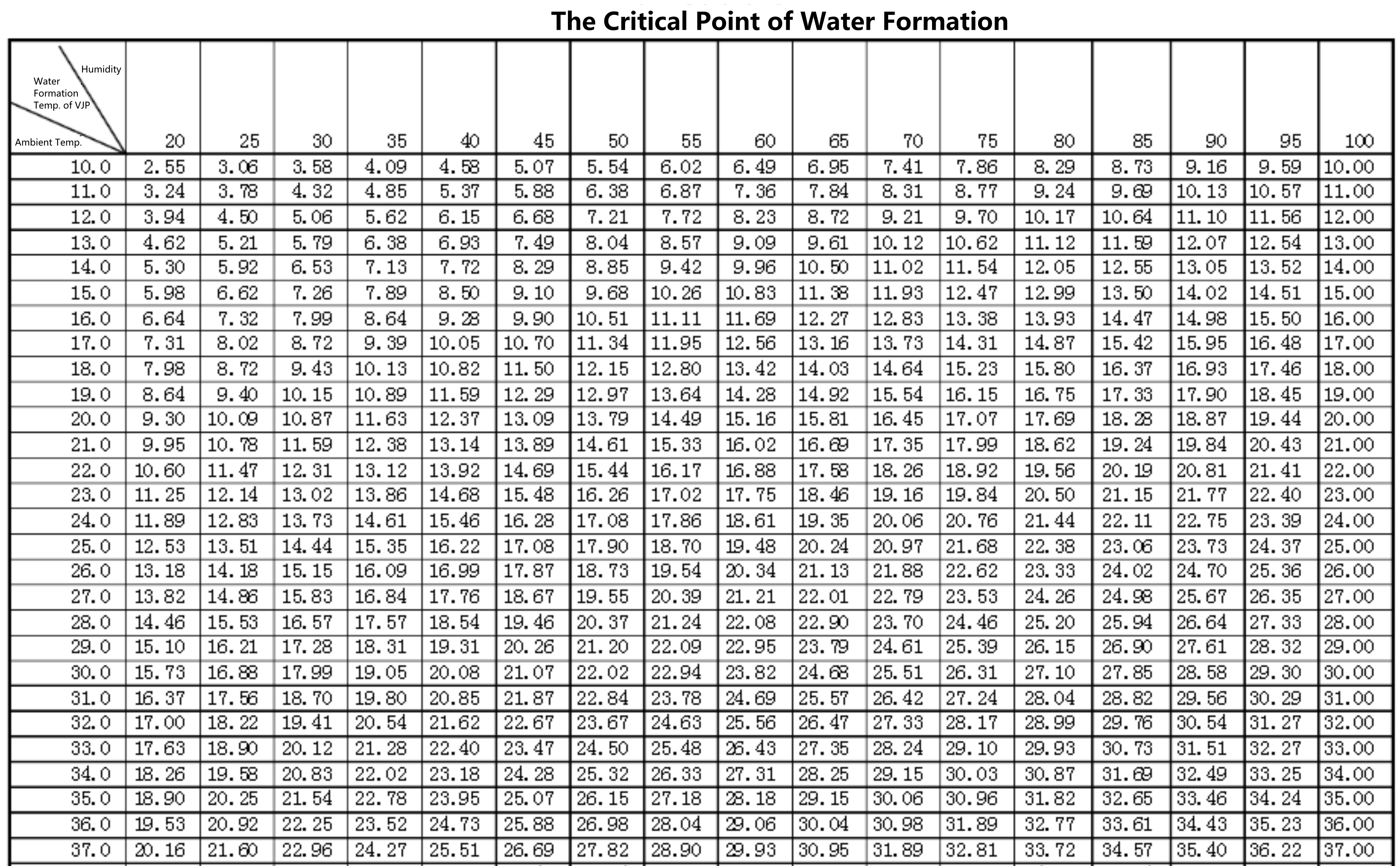

First of all, the insulated effect of the VI pipe is relative. When the outer wall temperature of the VI pipe is below the ambient temperature within 3 Kelvin (equal to 3℃), the quality of VI pipe is considered acceptable. Therefore, if the environmental humidity is relatively high at that time, when the temperature of VI pipe is less than 3 Kelvin from the environment, the water condensation phenomenon will also occur. Specific data are shown in the figure below.

For example, when the ambient humidity is 90% and the ambient temperature is 27℃, the critical temperature of water formation at this time is 25.67℃. That is to say, when the temperature difference between the VI pipe and the environment is 1.33℃, the phenomenon of water condensation will appear. However, the temperature difference of 1.33℃ is within the mass range of the VI pipe, so it is impossible to improve the water condensation condition by improving the quality of the VI pipe.

At this time, we suggest adding dehumidification equipment, opening the window for ventilation, and reducing the environmental humidity, so as to effectively improve the water condensation situation.

Post time: Jun-19-2021