What is a Vacuum Jacketed Hose?

Vacuum Jacketed Hose, also known as Vacuum Insulated Hose (VIH), is a flexible solution for transporting cryogenic liquids such as liquid nitrogen, oxygen, argon, and LNG. Unlike rigid piping, Vacuum Jacketed Hose is designed to be highly adaptable, allowing for greater flexibility in tight or dynamic spaces. By using vacuum insulation, these hoses minimize heat transfer, ensuring the cryogenic liquid remains at a stable low temperature during transit. The benefits of Vacuum Jacketed Hoses are particularly valued in industries requiring both flexibility and high-performance thermal insulation.

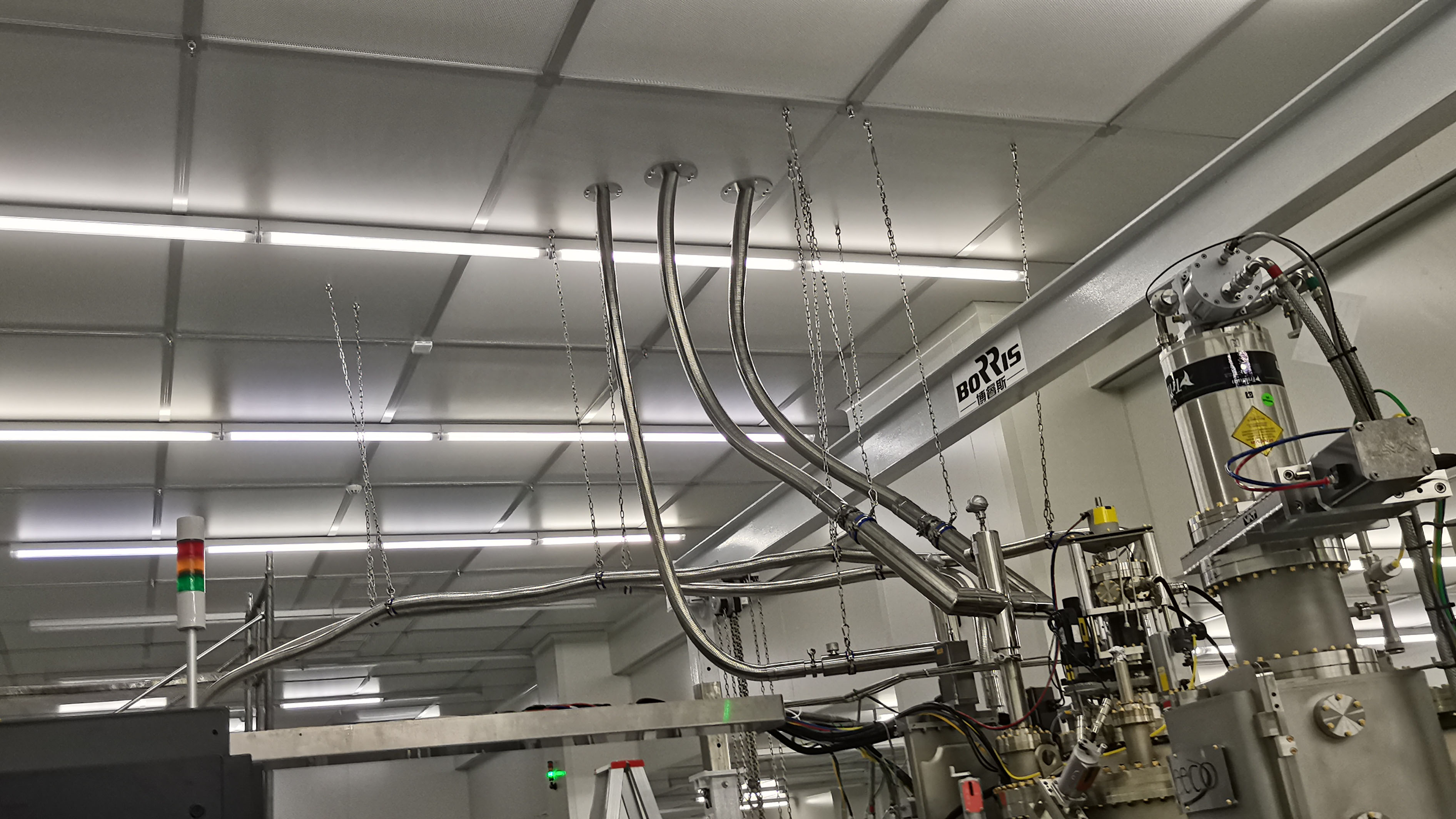

How Vacuum Jacketed Hoses are Constructed

The construction of Vacuum Jacketed Hose is unique and sophisticated, featuring an inner cryogenic tube and an outer jacket, usually made of stainless steel, with a vacuum-sealed space in between. The vacuum insulation acts as a barrier against heat transfer, reducing the risk of product evaporation and temperature fluctuation. Many hoses also contain multiple layers of reflective insulation material within the vacuum space to further enhance thermal performance. This specialized construction allows Vacuum Insulated Hoses to maintain optimal temperatures even in environments where movement and flexibility are crucial.

Applications of Vacuum Insulated Hose in Industry

Vacuum Insulated Hoses are commonly used across a range of industries. In healthcare, for example, they transport liquid nitrogen for cryopreservation and medical applications, offering flexibility in settings where rigid piping may not be feasible. In the food and beverage sector, these hoses facilitate rapid freezing and storage by safely moving cryogenic gases. They are also integral to laboratories and research facilities where precise handling of cryogenic substances is essential. The energy and aerospace industries benefit from Vacuum Jacketed Hoses as well, using them to transfer cryogenic fuel and other low-temperature substances in scenarios requiring mobility.

Advantages of Vacuum Jacketed Hose Technology

The flexibility and insulation efficiency of Vacuum Jacketed Hose make it a vital component in various industrial processes. One significant advantage is its adaptability; because Vacuum Insulated Hoses can be bent and positioned in complex layouts, they’re ideal for confined or frequently adjusted spaces. Additionally, the vacuum insulation helps prevent frost buildup on the outer surface, ensuring both operational safety and consistent product integrity. The use of Vacuum Jacketed Hoses can also lead to cost savings, as their insulation properties reduce cryogenic liquid loss and improve energy efficiency over time.

Future Innovations in Vacuum Jacketed Hose Design

With an increasing focus on sustainability and operational efficiency, innovations in Vacuum Jacketed Hose technology are on the rise. Future designs are likely to feature even more efficient insulating materials, increased durability, and enhanced automation capabilities that monitor temperature and flow. As industries continue to demand flexible and reliable solutions for cryogenic transport, Vacuum Insulated Hoses are set to play a larger role in reducing emissions and optimizing cryogenic operations.

Conclusion

Vacuum Jacketed Hose (Vacuum Insulated Hose) offers industries a flexible and efficient solution for transporting cryogenic liquids. Its advanced insulation technology and adaptable design make it suitable for diverse applications, from healthcare to energy. As Vacuum Jacketed Hose technology continues to evolve, it promises enhanced sustainability, efficiency, and safety, making it a valuable investment for industries handling cryogenic substances.

Post time: Oct-31-2024