In the automotive industry, manufacturing processes are continuously evolving to improve efficiency, quality, and precision. One area where this is particularly important is in the assembly of automotive seat frames, where cold assembly techniques are used to ensure proper fitting and safety. Vacuum jacketed pipes (VJP) are a key technology that plays an essential role in these processes, providing superior insulation to maintain the required low temperatures during the cold assembly of seat frames.

What are Vacuum Jacketed Pipes?

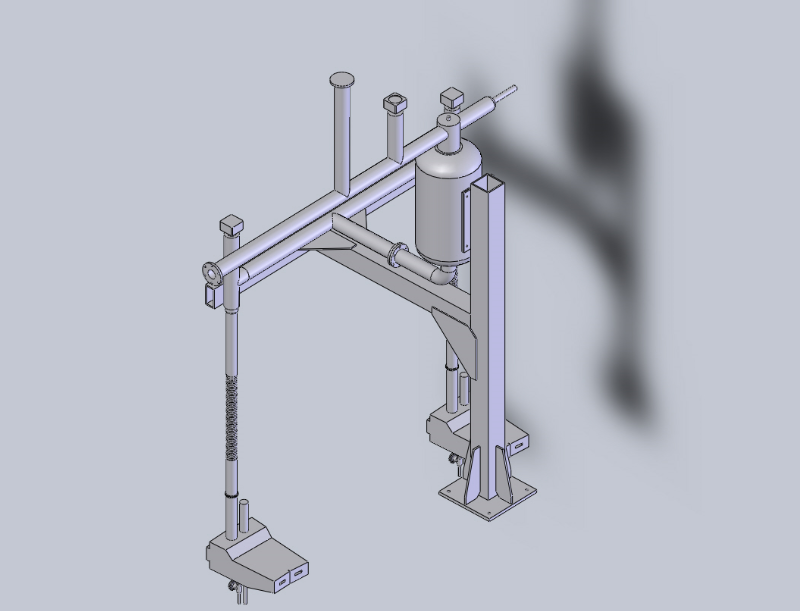

Vacuum jacketed pipes are specialized insulated pipes that feature a vacuum layer between two concentric pipe walls. This vacuum insulation effectively prevents heat transfer, maintaining the temperature of the fluid inside the pipe at a constant level, even when exposed to external heat sources. In automotive seat frame cold assembly, vacuum jacketed pipes are used to transport cryogenic fluids, such as liquid nitrogen or CO2, to chill specific components, ensuring that they fit perfectly during assembly.

The Need for Vacuum Jacketed Pipes in Automotive Cold Assembly

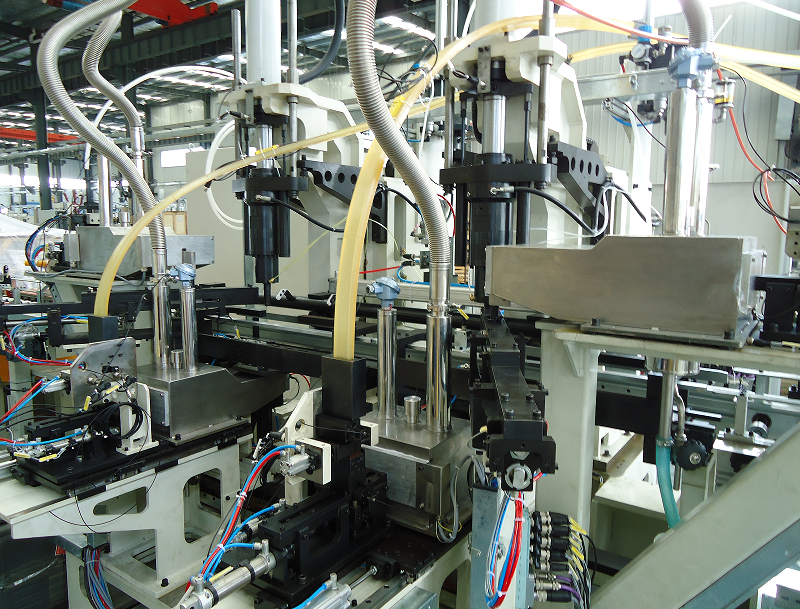

The cold assembly of automotive seat frames involves chilling certain parts of the seat, such as metal components, to reduce their temperature and shrink them slightly. This ensures tight fits and proper alignment without the need for additional mechanical force, minimizing the risk of material deformation. Vacuum jacketed pipes are crucial in these processes as they maintain the required low temperatures by preventing heat absorption from the environment. Without this thermal barrier, the cryogenic fluids would quickly warm up, leading to ineffective assembly.

Benefits of Vacuum Jacketed Pipes in Cold Assembly

1. Superior Thermal Insulation

One of the main advantages of vacuum jacketed pipes is their ability to maintain low temperatures for extended periods, even in challenging environments. The vacuum insulation layer drastically reduces heat gain, ensuring that cryogenic fluids such as liquid nitrogen remain at the optimal temperature throughout the process. This results in more efficient and effective cold assembly of automotive seat frames.

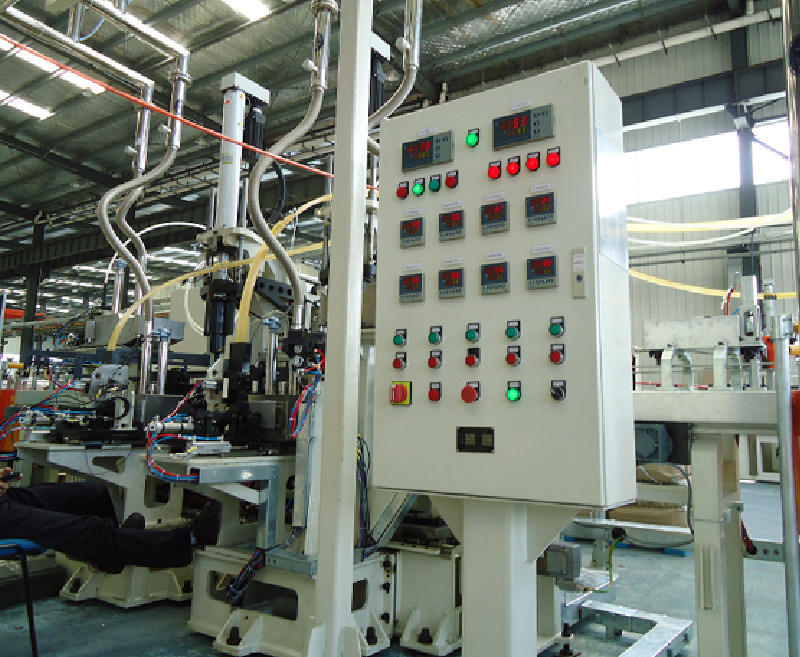

2. Enhanced Precision and Efficiency

Using vacuum jacketed pipes in the cold assembly process allows for precise control over the temperature of the components being chilled. This is particularly important in automotive manufacturing, where even the smallest variation in dimensions can affect the overall quality and safety of the seat frame. The precision and consistency provided by vacuum jacketed pipes contribute to a higher-quality end product and reduce the need for rework or adjustments.

3. Durability and Flexibility

Vacuum jacketed pipes are highly durable, designed to withstand extreme temperatures and mechanical stresses. They are often constructed from stainless steel or other high-strength materials, making them ideal for industrial applications. Additionally, vacuum jacketed pipes can be customized in terms of size and flexibility, allowing for easy integration into complex manufacturing systems for automotive seat frames.

Conclusion

In automotive manufacturing, particularly in the cold assembly of seat frames, the use of vacuum jacketed pipes offers significant advantages. Their superior thermal insulation properties, precision, and durability make them a crucial component in ensuring the efficiency and quality of the manufacturing process. By maintaining the required low temperatures for cryogenic fluids, vacuum jacketed pipes help automotive manufacturers achieve tight fits and reduce the risk of material deformation, ultimately leading to safer and more reliable vehicles. As the automotive industry continues to embrace more advanced technologies, vacuum jacketed pipes will remain an essential tool in optimizing cold assembly processes and improving overall production quality.

Vacuum jacketed pipes continue to play a vital role in many industrial applications, including automotive cold assembly, ensuring the effective use of cryogenic cooling techniques for a higher standard of precision and safety.

vacuum jacketed pipe:https://www.hlcryo.com/vacuum-insulated-pipe-series/

Post time: Dec-05-2024