Introduction to Liquid Nitrogen Transport

Liquid nitrogen, a crucial resource in various industries, requires precise and efficient transportation methods to maintain its cryogenic state. One of the most effective solutions is the use of vacuum insulated pipes (VIPs), which ensure the integrity and safety of liquid nitrogen during transport. This blog explores the application of vacuum insulated pipes in the transportation of liquid nitrogen, focusing on their principles, industry applications, and the integration of vacuum valves, phase separators, adsorbents, and getters.

Principles of Vacuum Insulated Pipe (VIP) Technology

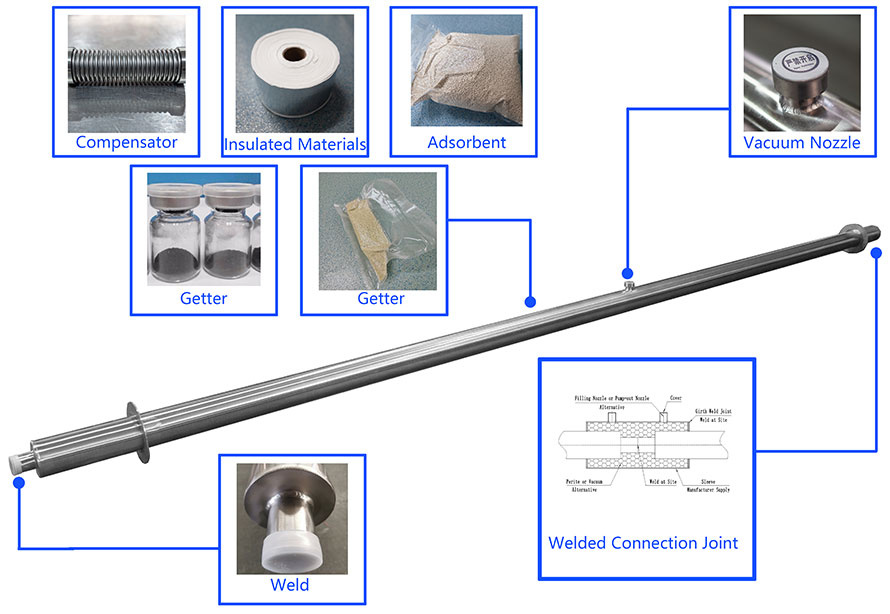

Vacuum insulated pipes are designed to minimize heat transfer and maintain the ultra-low temperatures required for liquid nitrogen. The structure of VIPs includes an inner pipe, which carries the liquid nitrogen, and an outer pipe, with a vacuum space in between. This vacuum acts as an insulator, drastically reducing thermal conductivity and preventing heat from penetrating the inner pipe.

The efficiency of VIPs is further enhanced by multilayer insulation materials, often composed of reflective foils and spacers, which minimize radiative heat transfer. Additionally, the vacuum space often contains adsorbents and getters to maintain the quality of the vacuum:

·Adsorbents: These materials, such as activated charcoal, are used to trap and hold residual gases and moisture within the vacuum space, preventing them from degrading the insulating properties of the vacuum.

·Getters: These are reactive materials that absorb and chemically bind with gas molecules, particularly those that adsorbents cannot capture effectively. Getters ensure that any outgassing that occurs over time is mitigated, maintaining the vacuum's integrity.

This construction ensures that liquid nitrogen remains at its required cryogenic temperature during transport, reducing losses and enhancing operational efficiency.

Applications in Various Industries

1.Medical and Pharmaceutical Industries: Liquid nitrogen is essential for cryopreservation, which includes storing biological samples and tissues. VIPs ensure that liquid nitrogen is transported efficiently to maintain the viability of these samples.

2.Food and Beverage Industry: In food processing, liquid nitrogen is used for flash freezing, preserving the quality and texture of products. VIPs enable reliable transport from production sites to storage facilities.

3.Electronics and Semiconductor Manufacturing: Liquid nitrogen is used in cooling processes for equipment and materials. VIPs ensure that these cooling systems operate effectively, maintaining the necessary low temperatures.

4.Chemical Manufacturing: In the chemical industry, liquid nitrogen is used for various applications such as cooling reactors, preserving volatile substances, and preventing oxidation. VIPs ensure that liquid nitrogen is transported safely and efficiently to support these critical processes.

5.Aerospace and Rocket Applications: Liquid nitrogen is crucial in the aerospace industry for cooling rocket engines and other components. VIPs provide the necessary infrastructure to transport liquid nitrogen efficiently, ensuring the precise thermal management required in these high-stakes environments.

Integration of Vacuum insulated Valves and Phase Separators

To enhance the functionality of vacuum insulated pipes, the integration of vacuum valves and phase separators is critical.

·Vacuum insulated Valves: These valves maintain the vacuum within the insulation layer of the VIP, ensuring consistent insulation performance over time. They are crucial for maintaining the efficiency and longevity of the vacuum insulated system.

·Phase Separators: In the liquid nitrogen transport system, phase separators play a vital role in separating gaseous nitrogen from liquid nitrogen. This ensures that only liquid nitrogen reaches the end-user application, maintaining the required temperature and preventing gas from disrupting the process.

Conclusion: Optimizing Liquid Nitrogen Transport

The use of vacuum insulated pipes in liquid nitrogen transport offers unparalleled efficiency and reliability across various industries. By incorporating advanced technologies like vacuum valves, phase separators, adsorbents, and getters, these systems provide a robust solution for maintaining cryogenic temperatures during transport. The precise and efficient delivery of liquid nitrogen facilitated by VIPs supports critical applications in medical, food processing, electronics, chemical manufacturing, and aerospace sectors, ensuring that these industries can operate smoothly and effectively.

Post time: May-25-2024