Vacuum Insulated Pipes and Liquefied Natural Gas: A Perfect Partnership

The liquefied natural gas (LNG) industry has experienced significant growth due to its efficiency in storage and transportation. A key component that has contributed to this efficiency is the use of vacuum insulated pipes (VIP). These pipes play a crucial role in maintaining the cryogenic required for LNG. This article explores the importance and applications of VIP in the LNG sector, highlighting the advanced features and benefits they offer.

The Critical Role of Vacuum Insulated Pipes in LNG Transport

LNG must be stored at extremely low temperatures, around -162°C (-260°F), to remain in liquid form. Vacuum insulated pipes are engineered to handle these cryogenic conditions. These pipes consist of a stainless-steel core surrounded by an outer jacket, with a vacuum space in between that significantly reduces heat transfer. This design ensures that the LNG remains at a stable temperature during transportation, minimizing boil-off gas (BOG) losses and enhancing safety and efficiency.

Key Features of Vacuum Insulated Pipes

Vacuum insulated pipes, such as those produced by Holy Cryogenic Equipment Co., Ltd., exhibit several critical features:

● Material: The inner pipes are made from 300 series stainless steel, known for its strength and resistance to cryogenic temperatures.

● Insulation: The vacuum space is often filled with multiple layers of highly reflective materials like aluminum foil, which further reduce heat transfer through radiation. Additionally, the space contains adsorbents and getters to maintain the vacuum and absorb any residual gases.

● Connections: These pipes can be connected using both flanges and welding, providing flexibility in installation and maintenance.

● Efficiency: The vacuum insulation ensures minimal heat ingress, reducing the need for frequent recirculation or re-liquefaction of LNG.

Applications and Benefits in the LNG Industry

The use of VIPs in the LNG industry is widespread due to their superior thermal insulation properties. These pipes are particularly beneficial in the following areas:

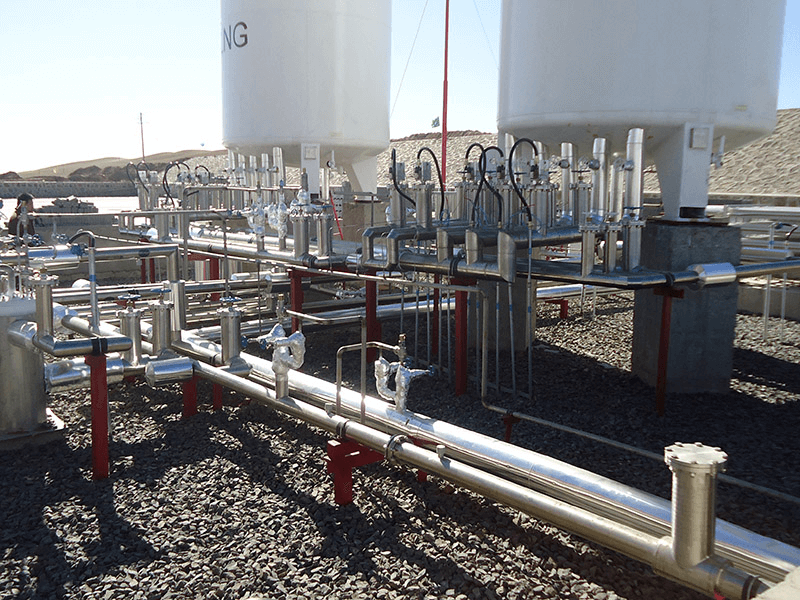

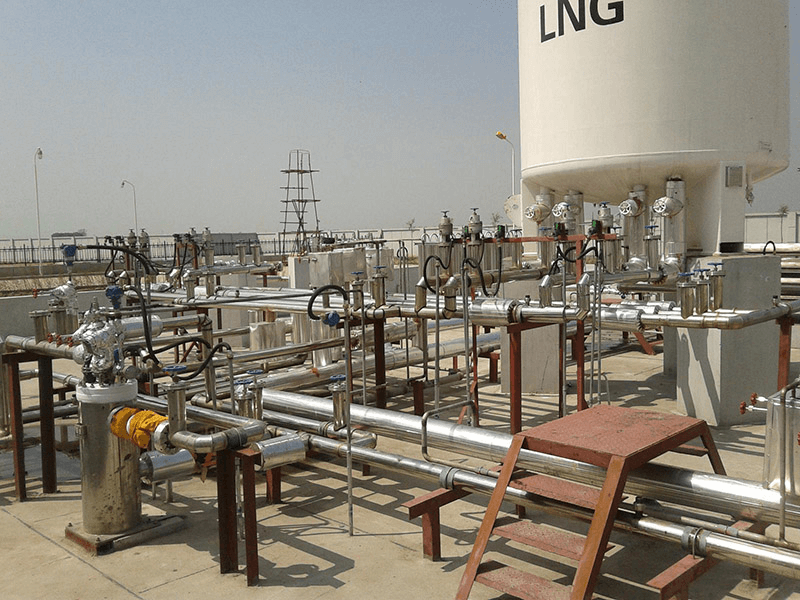

● LNG Terminals: VIPs help in maintaining the cryogenic required for LNG storage and transfer, reducing operational costs associated with heat loss.

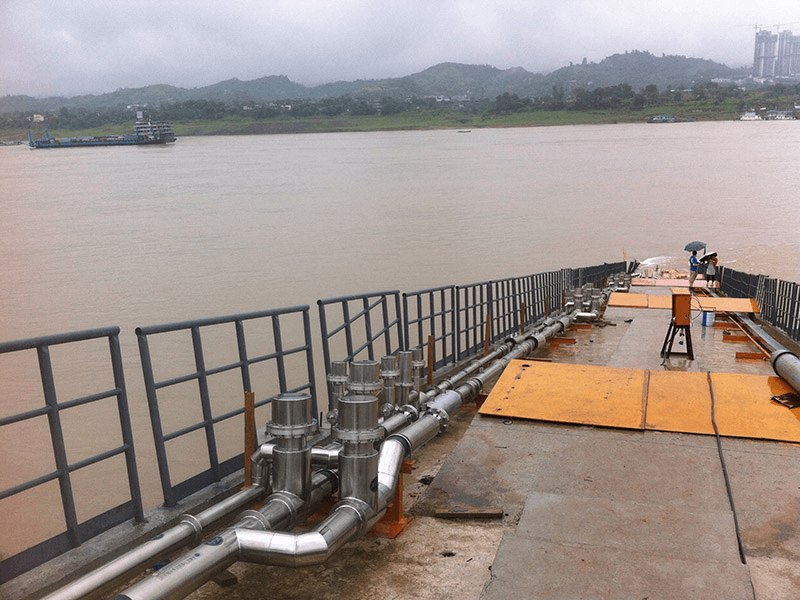

● Transportation: Whether by ship, truck, or rail, VIPs ensure that LNG remains in liquid form throughout the journey, preventing losses and maintaining safety.

● Industrial Use: In facilities where LNG is used as a fuel or a feedstock, VIPs provide a reliable means of transporting the gas to different parts of the plant without significant temperature fluctuations.

Recent Developments and Market Position

The demand for vacuum insulated pipes is growing, driven by the increasing use of LNG as a cleaner alternative to other fossil fuels. Companies like Holy Cryogenic Equipment Co., Ltd. have positioned themselves as leaders in this market by continually innovating and improving the design and efficiency of their products. Their VIPs are not only used domestically in China but are also exported to various international markets, reflecting their high quality and reliability.

Conclusion

Vacuum insulated pipes are indispensable in the LNG industry, providing the necessary thermal insulation to transport and store LNG efficiently. With advancements in technology and a growing emphasis on cleaner energy sources, the role of VIPs is set to become even more critical. Companies at the forefront of this technology are paving the way for a more efficient and sustainable LNG supply chain.

Contact Us

-

Phone: +86 28-85370666

-

Email: info@cdholy.com

Post time: Jun-12-2024