Safety Valve

Reliable Overpressure Protection: Our Safety Valves are carefully designed with precision components and pressure control mechanisms, guaranteeing reliable and accurate overpressure protection. They ensure smooth operations by promptly relieving any excess pressure, preventing hazardous situations.

Versatile Applications: From oil and gas refineries to chemical plants and power generation facilities, our Safety Valves are versatile and suitable for a wide range of industrial applications. They safeguard pipelines, tanks, and equipment, providing comprehensive safety measures tailored to specific industry requirements.

Compliance with International Standards: As a responsible manufacturing factory, we adhere to stringent quality standards, ensuring that our Safety Valves meet or exceed international industry regulations and certifications. This emphasis on compliance assures customers of the valves' reliability and performance in critical operations.

Customizable Solutions: Recognizing that every industrial system is unique, we offer a range of customizable options for our Safety Valves. This includes various sizes, materials, and pressure ratings to match specific application demands, resulting in a perfect fit and optimized safety performance.

Expert Engineering and Support: Our team of highly skilled engineers and customer support specialists are committed to providing personalized assistance throughout the valve selection, installation, and maintenance processes. We are here to ensure that our customers receive the best solutions and support required for their safety needs.

Product Application

The all series of vacuum insulated equipment in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (e.g. cryogenic tank, dewar and coldbox etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, pharmacy, cellbank, food & beverage, automation assembly, chemical engineering, iron & steel, and scientific research etc.

Safety Relief Valve

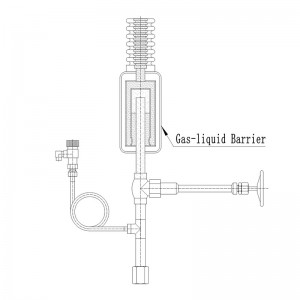

When the pressure in the VI Piping System is too high, the Safety Relief Valve and the Safety Relief Valve Group can automatically relieve pressure to ensure the safe operation of the pipeline.

A Safety Relief Valve or Safety Relief Valve Group must be placed between two shut-off valves. Prevent cryogenic liquid vaporization and pressure boost in VI pipeline after both ends of valves are shut off at the same time, leading to damage to equipment and safety hazards.

The Safety Relief Valve Group is composed of two safety relief valves, a pressure gauge, and a shut-off valve with a manual discharge port. Compared to a single safety relief valve, it can be repaired and operated separately when the VI Piping is working.

Users can purchase the Safety Relief Valves by yourselves, and HL reserves the installation connector of the Safety Relief Valve on the VI Piping.

For more personalized and detailed questions, please contact HL Cryogenic Equipment Company directly, we will serve you whole-heartedly!

Parameter Information

| Model | HLER000 Series |

| Nominal Diameter | DN8 ~ DN25 (1/4" ~ 1") |

| Working Pressure | Adjustable according to user needs |

| Medium | LN2, LOX, LAr, LHe, LH2, LNG |

| Material | Stainless Steel 304 |

| On-site Installation | No |

| Model | HLERG000 Series |

| Nominal Diameter | DN8 ~ DN25 (1/4" ~ 1") |

| Working Pressure | Adjustable according to user needs |

| Medium | LN2, LOX, LAr, LHe, LH2, LNG |

| Material | Stainless Steel 304 |

| On-site Installation | No |