Special Design for Argon Tank - Vacuum Insulated Phase Separator Series – Holy

Special Design for Argon Tank - Vacuum Insulated Phase Separator Series – Holy Detail:

Product Application

The product series of Phase Separator, Vacuum Pipe, Vacuum Hose and Vacuum Valve in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (e.g. cryogenic storage tank, dewar and coldbox etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, pharmacy, biobank, food & beverage, automation assembly, chemical engineering, iron & steel, rubber, new material manufacturing and scientific research etc.

Vacuum Insulated Phase Separator

The Vacuum Insulated Phase Separator, namely Vapor Vent, is one of the most common equipment of Vacuum Insulated Cryogenic Piping System. The phase separator is mainly to separate the gas from the cryogenic liquid, which can ensure,

1. Liquid supply volume and speed: eliminate insufficient liquid flow and velocity caused by gas barrier.

2. Incoming temperature of terminal equipment: eliminate the temperature instability of cryogenic liquid due to slag inclusion in gas, which leads to the production conditions of terminal equipment.

3. Pressure adjustment (reducing) and stability: eliminate the pressure fluctuation caused by the continuous formation of gas.

The Phase Separator is a mechanical structure and system that does not require pneumatic and electrical source. Usually choose 304 stainless steel production, can also choose other 300 series stainless steel according to the requirements. The Phase Separator is mainly used for liquid nitrogen service and recommended to be placed at the highest point of the piping system to ensure maximum effect, since gas has a lower specific gravity than liquid.

There are three type of separators to satisfy various demands,

1.HLSP1000 series, a common phase separator.

2.HLSR1000 series, a pressure step-down regulating phase separator and suitable for some special control requirements.

3.HLSC1000 series, a special phase separator uses for Molecular Beam Epitaxy (MBE) System.

About the Phase Separator / Vapor Vent more personalized and detailed questions, please contact HL Cryogenic Equipment directly, we will serve you whole-heartedly!

Parameter Information

| Name | Phase Separator |

| Model | HLSP1000 |

| Pressure Regulation | No |

| Design Pressure | ≤40bar (4.0MPa) |

| Design Temperature | -196℃~ 60℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 10L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Description |

|

| Name | Pressure Regulating Phase Separator |

| Model | HLSR1000 |

| Pressure Regulation | Yes |

| Design Pressure | ≤40bar (4.0MPa) |

| Design Temperature | -196℃~ 60℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 10L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Description |

|

| Name | Special Phase Separator for MBE Equipment |

| Model | HLSC1000 |

| Pressure Regulation | No |

| Design Pressure | Determine according to MBE Equipment |

| Design Temperature | -196℃~ 60℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | Determine according to MBE Equipment |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

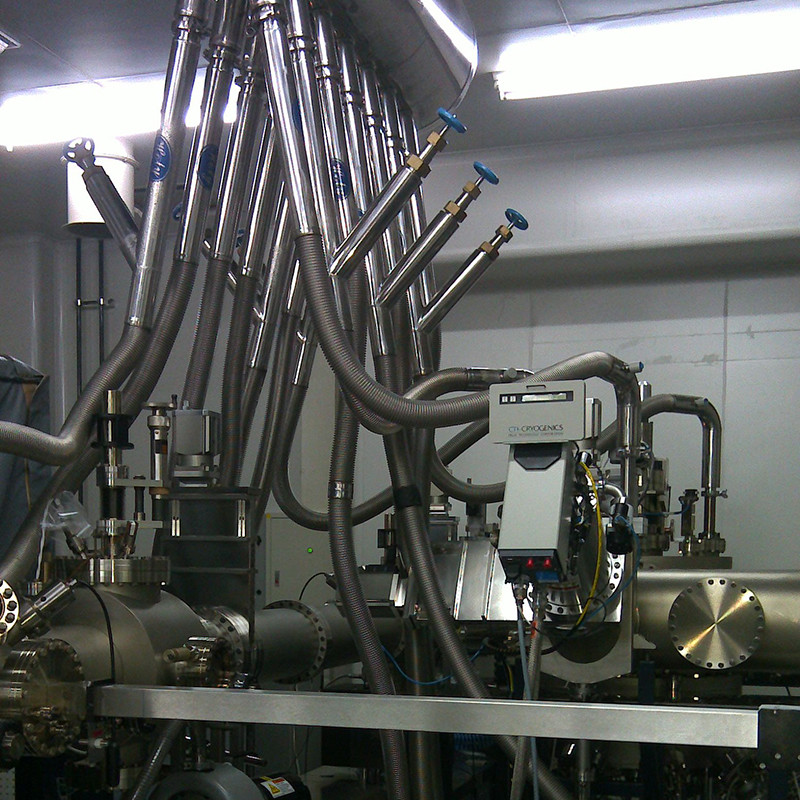

| Description | A Special Phase Separator for MBE equipment with Multiple Cryogenic Liquid Inlet and Outlet with automatic control function meets the requirement of gas emission, recycled liquid nitrogen and temperature of liquid nitrogen.

|

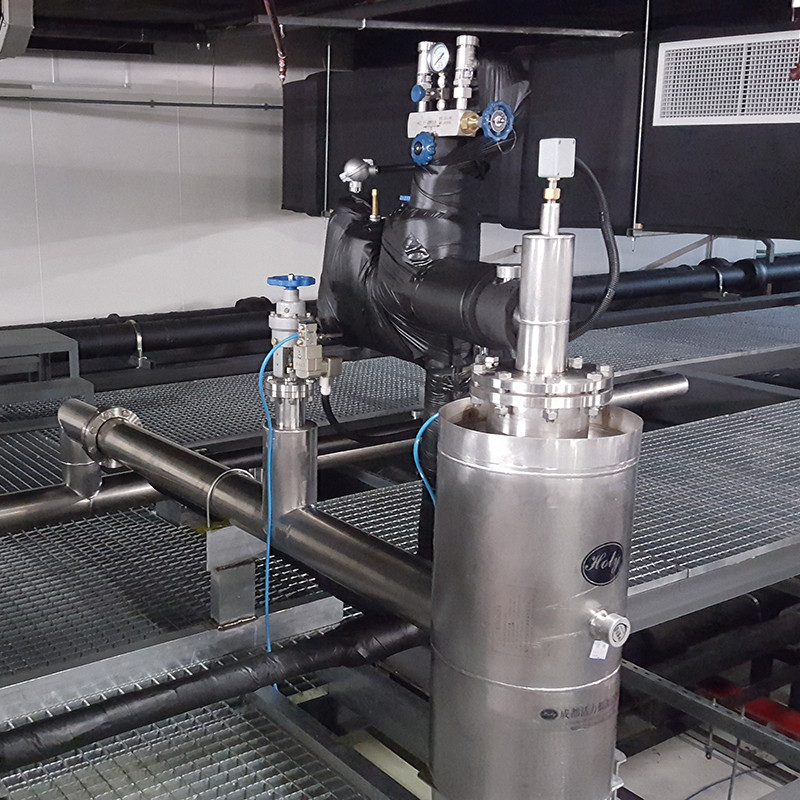

Product detail pictures:

Related Product Guide:

We pursue the management tenet of "Quality is remarkable, Company is supreme, Name is first", and will sincerely create and share success with all clientele for Special Design for Argon Tank - Vacuum Insulated Phase Separator Series – Holy , The product will supply to all over the world, such as: Palestine, Czech republic, Hungary, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We have been able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to deliver you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. You should feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.