Vacuum Insulation Phase Separator Series

Advanced Thermal Insulation: Engineered with cutting-edge technology, the Vacuum Insulation Phase Separator Series creates an efficient thermal barrier between fluids and the environment. The vacuum layer significantly reduces heat transfer, thus minimizing energy waste and facilitating consistent fluid temperatures.

Unmatched Durability and Reliability: Crafted using premium-grade materials, our Vacuum Insulation Phase Separator Series ensures exceptional durability and reliability. Its resistance to corrosive substances, extreme temperatures, and mechanical stress ensures long-lasting insulation performance under demanding conditions.

Effortless Installation and Customization: Installing our Vacuum Insulation Phase Separator Series is a seamless and time-efficient process. User-friendly features enable hassle-free integration into existing systems. Moreover, we provide customizable options to meet specific project requirements, ensuring a perfect fit.

Environmentally Friendly Solution: By reducing heat loss and minimizing energy consumption, our Vacuum Insulation Phase Separator Series contributes to environmental sustainability. Its efficient insulation properties help curtail carbon emissions, potentially earning businesses recognition for their eco-conscious efforts.

Versatile Applications: The Vacuum Insulation Phase Separator Series finds extensive application across a diverse range of industries. Its reliability in manufacturing plants, energy production facilities, and other industrial settings maximizes energy efficiency and system performance, offering a robust insulation solution.

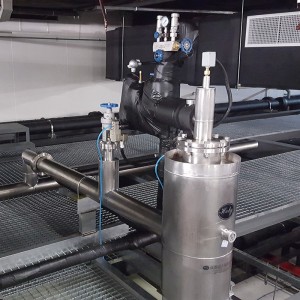

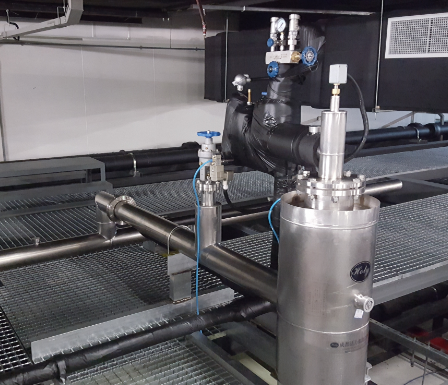

Product Application

The product series of Phase Separator, Vacuum Pipe, Vacuum Hose and Vacuum Valve in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (e.g. cryogenic storage tank, dewar and coldbox etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, pharmacy, biobank, food & beverage, automation assembly, chemical engineering, iron & steel, rubber, new material manufacturing and scientific research etc.

Vacuum Insulated Phase Separator

HL Cryogenic Equipment Company has four kinds of Vacuum Insulated Phase Separator, their name are,

- VI Phase Separator -- (HLSR1000 series)

- VI Degasser -- (HLSP1000 series)

- VI Automatic Gas Vent -- (HLSV1000 series)

- VI Phase Separator for MBE System -- (HLSC1000 series)

No matter which kind of the Vacuum Insulated Phase Separator, it is one of the most common equipment of Vacuum Insulated Cryogenic Piping System. The phase separator is mainly to separate the gas from the liquid nitrogen, which can ensure,

1. Liquid supply volume and speed: Eliminate insufficient liquid flow and velocity caused by gas barrier.

2. Incoming temperature of terminal equipment: eliminate the temperature instability of cryogenic liquid due to slag inclusion in gas, which leads to the production conditions of terminal equipment.

3. Pressure adjustment (reducing) and stability: eliminate the pressure fluctuation caused by the continuous formation of gas.

In a word, VI Phase Separator function is to meet the requirements of the terminal equipment for liquid nitrogen, including flow rate, pressure, and temperature and so on.

The Phase Separator is a mechanical structure and system that does not require pneumatic and electrical source. Usually choose 304 stainless steel production, can also choose other 300 series stainless steel according to the requirements. The Phase Separator is mainly used for liquid nitrogen service and recommended to be placed at the highest point of the piping system to ensure maximum effect, since gas has a lower specific gravity than liquid.

About the Phase Separator / Vapor Vent more personalized and detailed questions, please contact HL Cryogenic Equipment directly, we will serve you whole-heartedly!

Parameter Information

| Name | Degasser |

| Model | HLSP1000 |

| Pressure Regulation | No |

| Power Source | No |

| Electric Control | No |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 8~40L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 265 W/h (when 40L) |

| Heat Loss When Is Stable | 20 W/h (when 40L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Phase Separator |

| Model | HLSR1000 |

| Pressure Regulation | Yes |

| Power Source | Yes |

| Electric Control | Yes |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 8L~40L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 265 W/h (when 40L) |

| Heat Loss When Is Stable | 20 W/h (when 40L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Automatic Gas Vent |

| Model | HLSV1000 |

| Pressure Regulation | No |

| Power Source | No |

| Electric Control | No |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 4~20L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 190W/h (when 20L) |

| Heat Loss When Is Stable | 14 W/h (when 20L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Special Phase Separator for MBE Equipment |

| Model | HLSC1000 |

| Pressure Regulation | Yes |

| Power Source | Yes |

| Electric Control | Yes |

| Automatic Working | Yes |

| Design Pressure | Determine according to MBE Equipment |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | ≤50L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 300 W/h (when 50L) |

| Heat Loss When Is Stable | 22 W/h (when 50L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description | A Special Phase Separator for MBE equipment with Multiple Cryogenic Liquid Inlet and Outlet with automatic control function meets the requirement of gas emission, recycled liquid nitrogen and temperature of liquid nitrogen. |