Vacuum Jacketed Flexible Hose Series

Introduction: As a reputable manufacturing factory, we take pride in presenting our Vacuum Jacketed Flexible Hose Series. This product line features vacuum insulated globe valves that provide outstanding performance for a variety of applications. In this product introduction, we will highlight the key selling points and company advantages of our Vacuum Jacketed Flexible Hose Series.

Product Highlights:

- Superior Insulation: Our Vacuum Jacketed Flexible Hose Series is designed with a high-quality vacuum insulation, which significantly reduces heat transfer and ensures exceptional thermal efficiency.

- Flexibility: These hoses are incredibly flexible, allowing for easy installation and connection to various systems.

- Durability: Constructed from robust materials, our hoses are resistant to wear and tear, ensuring a long-lasting product life.

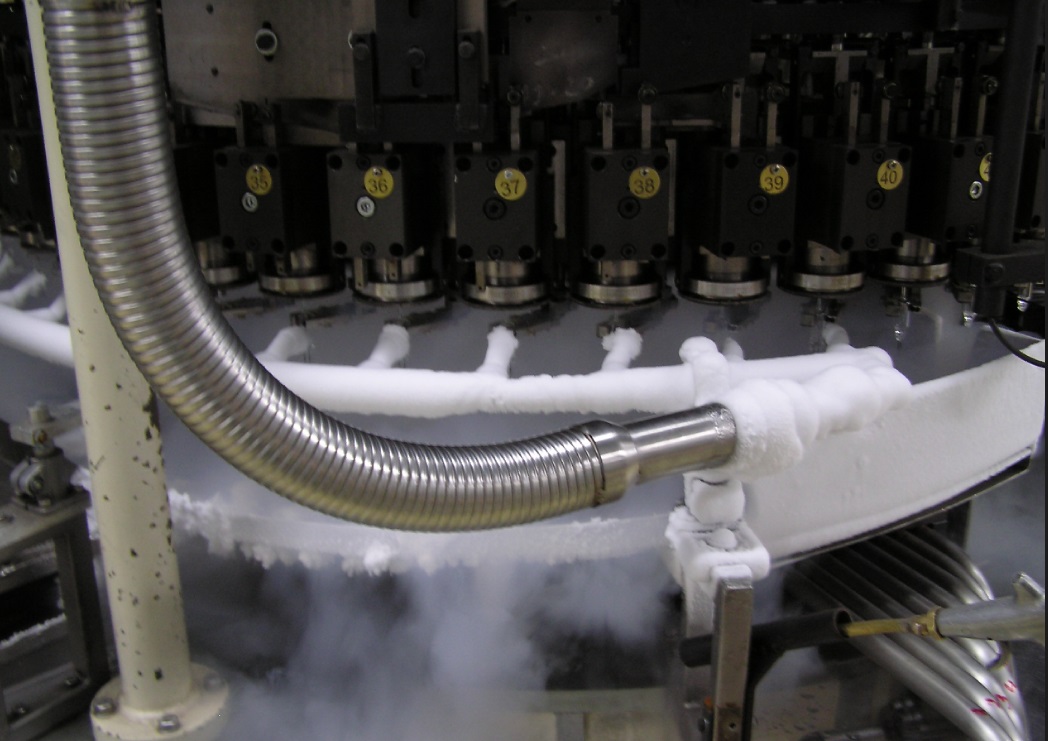

- Versatility: The Vacuum Jacketed Flexible Hose Series is suitable for use in a wide range of industries, including cryogenics, pharmaceuticals, chemical processing, and more.

- Customization: We offer customization options to meet the specific requirements of our customers, ensuring that our hoses fit seamlessly into their applications.

Product Details:

- Vacuum Insulated Globe Valve: Our Vacuum Jacketed Flexible Hose Series includes a high-performing vacuum insulated globe valve. This valve is designed to provide an efficient seal in cryogenic systems, ensuring optimal performance and minimal loss of pressure. The valve mechanism is engineered for smooth operation, allowing for precise control of the flow of gases or liquids.

- Exceptional Thermal Efficiency: The vacuum insulation within the hose series offers excellent thermal efficiency by effectively minimizing heat transfer. This ensures minimal heat loss or gain in cryogenic processes, enhancing overall system performance and reducing energy consumption.

- Easy Installation and Maintenance: The flexibility of our Vacuum Jacketed Flexible Hoses facilitates easy installation, making it simple to connect with existing systems. Additionally, the low-maintenance design of these hoses saves both time and resources, making them a cost-effective choice for our customers.

- Extensive Application Range: The Vacuum Jacketed Flexible Hoses are perfect for a wide range of applications, including cryogenic storage, transfer of liquefied gases, laboratory experiments, and more. The hoses maintain low temperatures and ensure the safe and efficient transfer of cold media within various industries.

In conclusion, our Vacuum Jacketed Flexible Hose Series, featuring the Vacuum Insulated Globe Valve, offers exceptional performance, reliability, and versatility. With its superior insulation properties, flexible design, and compatibility with various industries, this product line is the ideal choice for customers seeking reliable and efficient cryogenic solutions. Contact us today to discuss your specific requirements and benefit from our specialized customization options.

Video

Vacuum Insulated Piping

Vacuum Insulated Hose (vacuum hose), namely Vacuum Jacketed Hose, as a Perfect substitute for conventional piping insulation. Compared with conventional piping insulation, the heat leakage value of VIP is only 0.05~0.035 times of conventional piping insulation. Significantly save energy and cost for customers.

The product series of Vacuum Insulated Hose, Vacuum Insulated Pipe, Vacuum Insulated Valve, and Phase Separator in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (e.g. cryogenic tank, dewar and coldbox etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, pharmacy, hospital, biobank, food & beverage, automation assembly, rubber, new material manufacturing chemical engineering, iron & steel, and scientific research etc.

Four Connection Types

In order to maximize the different needs of customers, there are usually four connection types for VI Flexible Hose. The first three connection types apply only to the connection positions between VI Flexible Hoses. The fourth one, threaded connection type is generally used only for VI Hose connections to equipment and storage tank.

When VI Flexible Hose connects with equipment, storage tank and so on, the connection joint can be customized according to customer requirements.

Scope of Application

|

Vacuum Bayonet Connection Type with Clamps |

Vacuum Bayonet Connection Type with Flanges and Bolts |

Welded Connection Type |

Thread Joint Connection Type |

|

|

Connection Type |

Clamps |

Flanges and Bolts |

Weld |

Thread |

|

Insulation Type at joints |

Vacuum |

Vacuum |

Perlite or Vacuum |

Wrapping Insulated Materials |

|

On-site Insulated Treatment |

No |

No |

Yes, perlite filled into or vacuum pump out from the Insulated Sleeves at joints. |

Yes |

|

Nominal Diameter of Inner Pipe |

DN10(3/8")~DN25(1") |

DN10(3/8")~DN80(3") |

DN10(3/8")~DN150(6") |

DN10(3/8")~DN25(1") |

|

Design Pressure |

≤8 bar |

≤16 bar |

≤40 bar |

≤16 bar |

|

Installation |

Easy |

Easy |

Weld |

Easy |

|

Design Temperature |

-196℃~ 90℃ (LH2 & LHe:-270℃ ~ 90℃) |

|||

|

Length |

≥ 1 meter/pcs |

|||

|

Material |

300 Series Stainless Steel |

|||

|

Medium |

LN2, LOX, LAr, LHe, LH2, LNG |

|||

Protective Cover

Product Scope of Supply

|

Product |

Specification |

Vacuum Bayonet Connection with Clamps |

Vacuum Bayonet Connection with Flanges and Bolts |

Weld Insulated Connection |

Thread Connection |

|

Vacuum Insulated Flexible Hose |

DN8 |

YES |

YES |

YES |

YES |

|

DN15 |

YES |

YES |

YES |

YES |

|

|

DN20 |

YES |

YES |

YES |

YES |

|

|

DN25 |

YES |

YES |

YES |

YES |

|

|

DN32 |

/ |

YES |

YES |

/ |

|

|

DN40 |

/ |

YES |

YES |

/ |

|

|

DN50 |

/ |

YES |

YES |

/ |

|

|

DN65 |

/ |

YES |

YES |

/ |

|

|

DN80 |

/ |

YES |

YES |

/ |

|

|

DN100 |

/ |

/ |

YES |

/ |

|

|

DN125 |

/ |

/ |

YES |

/ |

|

|

DN150 |

/ |

/ |

YES |

/ |

Technical Characteristic

| Design Temperature | -196~90℃ (LHe:-270~90℃) |

| Ambient Temperature | -50~90℃ |

| Vacuum Leakage Rate | ≤1*10-10Pa*m3/S |

| Vacuum Level after Guarantee | ≤0.1 Pa |

| Insulated Method | High Vacuum Multi-Layer Insulation. |

| Adsorbent and Getter | Yes |

| Test Pressure | 1.15 Times Design Pressure |

| Medium | LO2、LN2、LAr、LH2、LHe、LEG、LNG |

Dynamic and Static Vacuum Insulated Flexible Hose

Vacuum Insulated (VI) Flexible Hose can be divided into Dynamic and Static VI Flexible Hose.

l The Static VI Hose is fully completed in the manufacturing factory.

l The Dynamic VI System is offered a more stable vacuum state by a continuous pumping of vacuum pump system on site, and vacuuming treatment will no longer take place in the factory. The rest of the assembly and process treatment is still in the manufacturing factory. So, the Dynamic VJ Piping needs to be equipped with a Vacuum Pump System.

| Dynamic Vacuum Insulated Flexible Hose | Static Vacuum Insulated Flexible Hose | |

| Introduction | The vacuum degree of the vacuum interlayer is monitored continuously, and the vacuum pump is automatically controlled to open and close, to ensure the stability and effectiveness of vacuum degree | VJ Flexible Hoses complete the vacuum insulation work in the manufacturing plant. |

| Advantages | The vacuum retention is more stable, basically eliminate the vacuum maintenance in the future working. | More economical investment and simple on-site installation |

| Vacuum Bayonet Connection Type with Clamps |

Applicative |

Applicative |

| Vacuum Bayonet Connection Type with Flanges and Bolts |

Applicative |

Applicative |

| Welded Connection Type |

Applicative |

Applicative |

| Thread Joint Connection Type |

Applicative |

Applicative |

Dynamic Vacuum Insulated Flexible Hose System: Consist of Vacuum Flexible Hoses, Jumper Hoses and Vacuum Pump System (including the vacuum pumps, solenoid valves and vacuum gauges). Easily installed in small room. The length of single Vacuum Insulated Flexible Hose can be customized according to customer’s requirements.

2.SPECIFICATION AND MODEL

HL-HX-X-000-00-X

Brand

HL Cryogenic Equipment

Description

HD: Dynamic VI Hose

HS: Static VI Hose

Connection Type

W: Welded Connection Type

B: Vacuum Bayonet Connection Type with Clamps

F: Vacuum Bayonet Connection Type with Flanges and bolts

T:Thread Joint Connection Type

Nominal Diameter of Inner Pipe

010: DN10

…

080: DN80

…

150: DN150

Design Pressure

08: 8bar

16: 16bar

25: 25bar

32: 32bar

40: 40bar

Material of Inner Pipe

A: SS304

B: SS304L

C: SS316

D: SS316L

E: Other

3.1 Static Vacuum Insulated Cryogenic Flexible Hose

|

Model |

Connection Type |

Nominal Diameter of Inner Pipe |

Design Pressure |

Material of Inner Pipe |

Standard |

Remark |

|

HLHSB01008X |

Vacuum Bayonet Connection Type with Clamps for Static Vacuum Insulated Flexible Hose |

DN10, 3/8" |

8 bar

|

300 Series Stainless Steel |

ASME B31.3 |

X:

Material of Inner Pipe. A is 304, B is 304L, C is 316, D is 316L, E is other. |

|

HLHSB01508X |

DN15, 1/2" |

|||||

|

HLHSB02008X |

DN20, 3/4" |

|||||

|

HLHSB02508X |

DN25, 1" |

Nominal Diameter of Inner Pipe: Recommended ≤ DN25 or 1". Or selects the Vacuum Bayonet Connection Type with Flanges and Bolts (from DN10, 3/8" to DN80, 3"), Welded Connection Type (from DN10, 3/8" to DN150, 6")

Nominal Diameter of Outer Pipe: Recommended by the Enterprise Standard of HL Cryogenic Equipment. It also can be produced according to requirement of the customer.

Design Pressure: Recommended ≤ 8 bar. Or selects the Vacuum Bayonet Connection Type with Flanges and Bolts (≤16 bar), Welded Connection Type (≤40 bar)

Material of Outer Pipe: Without special requirement, the material of inner pipe and outer pipe will be selected the same.

|

Model |

Connection Type |

Nominal Diameter of Inner Pipe |

Design Pressure |

Material of Inner Pipe |

Standard |

Remark |

|

HLHSF01000X |

Vacuum Bayonet Connection Type with Flanges and Bolts for Static Vacuum Insulated Flexible Hose |

DN10, 3/8" |

8~16 bar |

300 Series Stainless Steel |

ASME B31.3 |

00:

Design Pressure. 08 is 8bar, 16 is 16bar.

X: Material of Inner Pipe. A is 304, B is 304L, C is 316, D is 316L, E is other. |

|

HLHSF01500X |

DN15, 1/2" |

|||||

|

HLHSF02000X |

DN20, 3/4" |

|||||

|

HLHSF02500X |

DN25, 1" |

|||||

|

HLHSF03200X |

DN32, 1-1/4" |

|||||

|

HLHSF04000X |

DN40, 1-1/2" |

|||||

|

HLHSF05000X |

DN50, 2" |

|||||

|

HLHSF06500X |

DN65, 2-1/2" |

|||||

|

HLHSF08000X |

DN80, 3" |

Nominal Diameter of Inner Pipe: Recommended ≤ DN80 or 3". Or selects the Welded Connection Type (from DN10, 3/8" to DN150, 6"), Vacuum Bayonet Connection Type with Clamps (from DN10, 3/8" to DN25, 1").

Nominal Diameter of Outer Pipe: Recommended by the Enterprise Standard of HL Cryogenic Equipment. It also can be produced according to requirement of the customer.

Design Pressure: Recommended ≤ 16 bar. Or selects Welded Connection Type (≤40 bar).

Material of Outer Pipe: Without special requirement, the material of inner pipe and outer pipe will be selected the same.

|

Model |

Connection Type |

Nominal Diameter of Inner Pipe |

Design Pressure |

Material of Inner Pipe |

Standard |

Remark |

|

HLHSW01000X |

Welded Connection Type for Static Vacuum Insulated Flexible Hose |

DN10, 3/8" |

8~40 bar |

300 Series Stainless Steel |

ASME B31.3 |

00:

Design Pressure 08 is 8bar, 16 is 16bar, and 25, 32, 40.

X: Material of Inner Pipe. A is 304, B is 304L, C is 316, D is 316L, E is other. |

|

HLHSW01500X |

DN15, 1/2" |

|||||

|

HLHSW02000X |

DN20, 3/4" |

|||||

|

HLHSW02500X |

DN25, 1" |

|||||

|

HLHSW03200X |

DN32, 1-1/4" |

|||||

|

HLHSW04000X |

DN40, 1-1/2" |

|||||

|

HLHSW05000X |

DN50, 2" |

|||||

|

HLHSW06500X |

DN65, 2-1/2" |

|||||

|

HLHSW08000X |

DN80, 3" |

|||||

|

HLHSW10000X |

DN100, 4" |

|||||

|

HLHSW12500X |

DN125, 5" |

|||||

|

HLHSW15000X |

DN150, 6" |

Nominal Diameter of Outer Pipe: Recommended by the Enterprise Standard of HL Cryogenic Equipment. It also can be produced according to requirement of the customer.

Material of Outer Pipe: Without special requirement, the material of inner pipe and outer pipe will be selected the same.

|

Model |

Connection Type |

Nominal Diameter of Inner Pipe |

Design Pressure |

Material of Inner Pipe |

Standard |

Remark |

|

HLHST01000X |

Vacuum Bayonet Connection Type with Clamps for Static Vacuum Insulated Flexible Hose |

DN10, 3/8" |

8~16 bar |

300 Series Stainless Steel |

ASME B31.3 |

00:

Design Pressure. 08 is 8bar, 16 is 16bar.

X: Material of Inner Pipe. A is 304, B is 304L, C is 316, D is 316L, E is other. |

|

HLHSB01500X |

DN15, 1/2" |

|||||

|

HLHSB02000X |

DN20, 3/4" |

|||||

|

HLHSB02500X |

DN25, 1" |

Nominal Diameter of Inner Pipe: Recommended ≤ DN25 or 1". Or selects the Vacuum Bayonet Connection Type with Flanges and Bolts (from DN10, 3/8" to DN80, 3"), Welded Connection Type (from DN10, 3/8" to DN150, 6")

Nominal Diameter of Outer Pipe: Recommended by the Enterprise Standard of HL Cryogenic Equipment. It also can be produced according to requirement of the customer.

Design Pressure: Recommended ≤ 16 bar. Or selects the Welded Connection Type (≤40 bar)

Material of Outer Pipe: Without special requirement, the material of inner pipe and outer pipe will be selected the same.

3.2Dynamic Vacuum Insulated Piping System

|

Model |

Connection Type |

Nominal Diameter of Inner Pipe |

Design Pressure |

Material of Inner Pipe |

Standard |

Remark |

|

HLHDB01008X |

Vacuum Bayonet Connection Type with Clamps for Dynamic Vacuum Insulated Flexible Hose |

DN10, 3/8" |

8 bar

|

300 Series Stainless Steel |

ASME B31.3 |

X:Material of Inner Pipe.

A is 304, B is 304L, C is 316, D is 316L, E is other. |

|

HLHDB01508X |

DN15, 1/2" |

|||||

|

HLHDB02008X |

DN20, 3/4" |

|||||

|

HLHDB02508X |

DN25, 1" |

Nominal Diameter of Inner Pipe: Recommended ≤ DN25 or 1". Or selects the Vacuum Bayonet Connection Type with Flanges and Bolts (from DN10, 3/8" to DN80, 3"), Welded Connection Type (from DN10, 3/8" to DN150, 6")

Nominal Diameter of Outer Pipe: Recommended by the Enterprise Standard of HL Cryogenic Equipment. It also can be produced according to requirement of the customer.

Design Pressure: Recommended ≤ 8 bar. Or selects the Vacuum Bayonet Connection Type with Flanges and Bolts (≤16 bar), Welded Connection Type (≤40 bar)

Material of Outer Pipe: Without special requirement, the material of inner pipe and outer pipe will be selected the same.

Power Condition: The site needs to supply power to the vacuum pumps and inform HL Cryogenic Equipment the local electricity information (Voltage and Hertz).

|

Model |

Connection Type |

Nominal Diameter of Inner Pipe |

Design Pressure |

Material of Inner Pipe |

Standard |

Remark |

|

HLHDF01000X |

Vacuum Bayonet Connection Type with Flanges and Bolts for Dynamic Vacuum Insulated Flexible Hose |

DN10, 3/8" |

8~16 bar |

300 Series Stainless Steel |

ASME B31.3 |

00: Design Pressure.

08 is 8bar, 16 is 16bar.

X: Material of Inner Pipe. A is 304, B is 304L, C is 316, D is 316L, E is other. |

|

HLHDF01500X |

DN15, 1/2" |

|||||

|

HLHDF02000X |

DN20, 3/4" |

|||||

|

HLHDF02500X |

DN25, 1" |

|||||

|

HLHDF03200X |

DN32, 1-1/4" |

|||||

|

HLHDF04000X |

DN40, 1-1/2" |

|||||

|

HLHDF05000X |

DN50, 2" |

|||||

|

HLHDF06500X |

DN65, 2-1/2" |

|||||

|

HLHDF08000X |

DN80, 3" |

Nominal Diameter of Inner Pipe: Recommended ≤ DN80 or 3". Or selects the Welded Connection Type (from DN10, 3/8" to DN150, 6"), Vacuum Bayonet Connection Type with Clamps (from DN10, 3/8" to DN25, 1").

Nominal Diameter of Outer Pipe: Recommended by the Enterprise Standard of HL Cryogenic Equipment. It also can be produced according to requirement of the customer.

Design Pressure: Recommended ≤ 16 bar. Or selects Welded Connection Type (≤40 bar).

Material of Outer Pipe: Without special requirement, the material of inner pipe and outer pipe will be selected the same.

Power Condition: The site needs to supply power to the vacuum pumps and inform HL Cryogenic Equipment the local electricity information (Voltage and Hertz).

|

Model |

Connection Type |

Nominal Diameter of Inner Pipe |

Design Pressure |

Material of Inner Pipe |

Standard |

Remark |

|

HLHDW01000X |

Welded Connection Type for Dynamic Vacuum Insulated Flexible Hose |

DN10, 3/8" |

8~40 bar |

Stainless Steel 304, 304L, 316, 316L |

ASME B31.3 |

00:

Design Pressure 08 is 8bar, 16 is 16bar, and 25, 32, 40. .

X: Material of Inner Pipe. A is 304, B is 304L, C is 316, D is 316L, E is other. |

|

HLHDW01500X |

DN15, 1/2" |

|||||

|

HLHDW02000X |

DN20, 3/4" |

|||||

|

HLHDW02500X |

DN25, 1" |

|||||

|

HLHDW03200X |

DN32, 1-1/4" |

|||||

|

HLHDW04000X |

DN40, 1-1/2" |

|||||

|

HLHDW05000X |

DN50, 2" |

|||||

|

HLHDW06500X |

DN65, 2-1/2" |

|||||

|

HLHDW08000X |

DN80, 3" |

|||||

|

HLHDW10000X |

DN100, 4" |

|||||

|

HLHDW12500X |

DN125, 5" |

|||||

|

HLHDW15000X |

DN150, 6" |

Nominal Diameter of Outer Pipe: Recommended by the Enterprise Standard of HL Cryogenic Equipment. It also can be produced according to requirement of the customer.

Material of Outer Pipe: Without special requirement, the material of inner pipe and outer pipe will be selected the same.

Power Condition: The site needs to supply power to the vacuum pumps and inform HL Cryogenic Equipment the local electricity information (Voltage and Hertz).

|

Model |

Connection Type |

Nominal Diameter of Inner Pipe |

Design Pressure |

Material of Inner Pipe |

Standard |

Remark |

|

HLHDT01000X |

Vacuum Bayonet Connection Type with Clamps for Dynamic Vacuum Insulated Flexible Hose |

DN10, 3/8" |

8~16 bar |

300 Series Stainless Steel |

ASME B31.3 |

00:

Design Pressure. 08 is 8bar, 16 is 16bar.

X: Material of Inner Pipe. A is 304, B is 304L, C is 316, D is 316L, E is other. |

|

HLHDB01500X |

DN15, 1/2" |

|||||

|

HLHDB02000X |

DN20, 3/4" |

|||||

|

HLHDB02500X |

DN25, 1" |

Nominal Diameter of Inner Pipe: Recommended ≤ DN25 or 1". Or selects the Vacuum Bayonet Connection Type with Flanges and Bolts (from DN10, 3/8" to DN80, 3"), Welded Connection Type (from DN10, 3/8" to DN150, 6")

Nominal Diameter of Outer Pipe: Recommended by the Enterprise Standard of HL Cryogenic Equipment. It also can be produced according to requirement of the customer.

Design Pressure: Recommended ≤ 16 bar. Or selects the, Welded Connection Type (≤40 bar)

Material of Outer Pipe: Without special requirement, the material of inner pipe and outer pipe will be selected the same.

Power Condition: The site needs to supply power to the vacuum pumps and inform HL Cryogenic Equipment the local electricity information (Voltage and Hertz).