Vacuum Jacketed Phase Separator Series

Product Brief: Our Vacuum Jacketed Phase Separator Series, crafted by our esteemed manufacturing facility, is a state-of-the-art solution designed for efficient separation and temperature control of various phases in industrial processes. These separators, equipped with vacuum jacketing technology, provide exceptional performance, reliability, and flexibility for a wide range of applications.

Product Highlights and Company Advantages:

- Advanced Separation Efficiency: The Vacuum Jacketed Phase Separator Series optimizes separation efficiency by effectively separating liquids, gases, and solids. This ensures precise control of the process and allows for efficient and uninterrupted production.

- Vacuum Jacketing Technology: The incorporation of vacuum jacketing technology in these separators enhances thermal insulation, minimizing heat transfer and maintaining stable temperature control, even in demanding industrial conditions.

- Customizable Design: Our Vacuum Jacketed Phase Separators can be customized to meet specific process requirements. Whether it's the size, material, or additional features, our manufacturing facility can tailor the product to suit individual needs.

- Durability and Reliability: Crafted with superior craftsmanship and utilizing high-quality materials, these separators are designed to withstand harsh operating environments and offer reliable performance over an extended service life.

- Knowledgeable Support Team: Our team of experts is dedicated to providing personalized assistance, from selecting the right separator to on-site installation support, ensuring the smooth integration of the Vacuum Jacketed Phase Separator into your production process.

Product Details:

- Efficient Phase Separation:

- Separates various phases, including liquids, gases, and solids, ensuring precise process control and optimal production efficiency.

- Facilitates uninterrupted production by effectively removing unwanted components from the process stream.

- Vacuum Jacketing Technology:

- Vacuum-insulated design minimizes heat transfer, enabling precise temperature control.

- Ensures consistent and stable performance even in demanding industrial applications.

- Customizable Design:

- Tailored to meet specific process requirements, with options for size, material, and additional features.

- Enables integration into existing systems and process layouts.

- Durability and Reliability:

- Built with high-quality materials and precise craftsmanship for long-lasting performance.

- Well-suited for harsh operating conditions, providing reliable separation and temperature control.

- Expert Support:

- Knowledgeable experts provide personalized assistance, from product selection to on-site installation support.

- Ensures seamless integration of the Vacuum Jacketed Phase Separator into your production process.

Our Vacuum Jacketed Phase Separator Series offers unmatched separation efficiency, precise temperature control, and customizable design for your industrial processes. With vacuum jacketing technology, durable construction, and comprehensive support, our separators are engineered to enhance productivity and minimize downtime. Contact us today to learn more about our Vacuum Jacketed Phase Separator Series and experience improved process efficiency and control.

Product Application

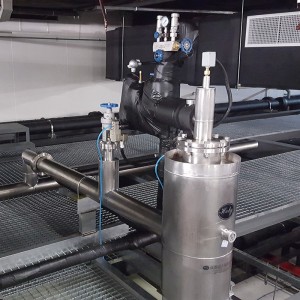

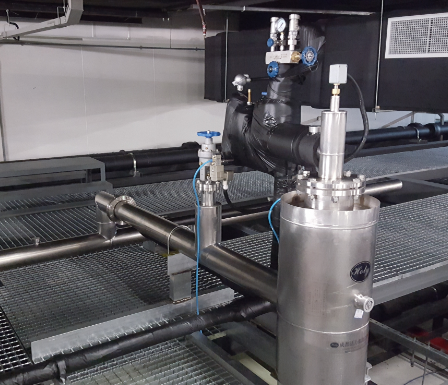

The product series of Phase Separator, Vacuum Pipe, Vacuum Hose and Vacuum Valve in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (e.g. cryogenic storage tank, dewar and coldbox etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, pharmacy, biobank, food & beverage, automation assembly, chemical engineering, iron & steel, rubber, new material manufacturing and scientific research etc.

Vacuum Insulated Phase Separator

HL Cryogenic Equipment Company has four kinds of Vacuum Insulated Phase Separator, their name are,

- VI Phase Separator -- (HLSR1000 series)

- VI Degasser -- (HLSP1000 series)

- VI Automatic Gas Vent -- (HLSV1000 series)

- VI Phase Separator for MBE System -- (HLSC1000 series)

No matter which kind of the Vacuum Insulated Phase Separator, it is one of the most common equipment of Vacuum Insulated Cryogenic Piping System. The phase separator is mainly to separate the gas from the liquid nitrogen, which can ensure,

1. Liquid supply volume and speed: Eliminate insufficient liquid flow and velocity caused by gas barrier.

2. Incoming temperature of terminal equipment: eliminate the temperature instability of cryogenic liquid due to slag inclusion in gas, which leads to the production conditions of terminal equipment.

3. Pressure adjustment (reducing) and stability: eliminate the pressure fluctuation caused by the continuous formation of gas.

In a word, VI Phase Separator function is to meet the requirements of the terminal equipment for liquid nitrogen, including flow rate, pressure, and temperature and so on.

The Phase Separator is a mechanical structure and system that does not require pneumatic and electrical source. Usually choose 304 stainless steel production, can also choose other 300 series stainless steel according to the requirements. The Phase Separator is mainly used for liquid nitrogen service and recommended to be placed at the highest point of the piping system to ensure maximum effect, since gas has a lower specific gravity than liquid.

About the Phase Separator / Vapor Vent more personalized and detailed questions, please contact HL Cryogenic Equipment directly, we will serve you whole-heartedly!

Parameter Information

| Name | Degasser |

| Model | HLSP1000 |

| Pressure Regulation | No |

| Power Source | No |

| Electric Control | No |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 8~40L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 265 W/h (when 40L) |

| Heat Loss When Is Stable | 20 W/h (when 40L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Phase Separator |

| Model | HLSR1000 |

| Pressure Regulation | Yes |

| Power Source | Yes |

| Electric Control | Yes |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 8L~40L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 265 W/h (when 40L) |

| Heat Loss When Is Stable | 20 W/h (when 40L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Automatic Gas Vent |

| Model | HLSV1000 |

| Pressure Regulation | No |

| Power Source | No |

| Electric Control | No |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 4~20L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 190W/h (when 20L) |

| Heat Loss When Is Stable | 14 W/h (when 20L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Special Phase Separator for MBE Equipment |

| Model | HLSC1000 |

| Pressure Regulation | Yes |

| Power Source | Yes |

| Electric Control | Yes |

| Automatic Working | Yes |

| Design Pressure | Determine according to MBE Equipment |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | ≤50L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 300 W/h (when 50L) |

| Heat Loss When Is Stable | 22 W/h (when 50L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description | A Special Phase Separator for MBE equipment with Multiple Cryogenic Liquid Inlet and Outlet with automatic control function meets the requirement of gas emission, recycled liquid nitrogen and temperature of liquid nitrogen. |